MicroHAWK F330 PoE Lite Industrial Smart Camera from Omron

May 30, 2025

Perfect for OEMs/machine builders, the F330 offers the ideal combination of size, performance. And flexible integration via RJ45 connection and active PoE.

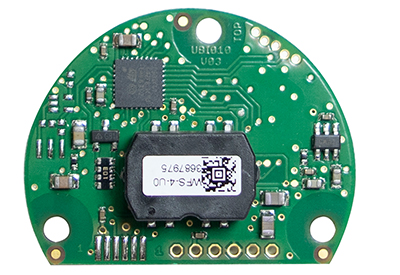

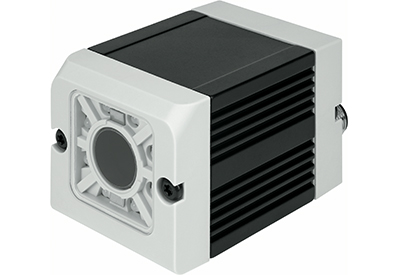

An OEM- and embedded application-focused smart camera available with multiple sensors and lens versions, the MicroHAWK F330 furthers Omron more-than-30-year legacy of innovative, space-efficient, miniature design with a locking RJ45 connection and active Power over Ethernet functionality. Perfect for OEMs and machine builders, the F330 offers the perfect combination of size, performance and flexible integration. It provides outstanding value and is the ideal solution for automation engineers looking for a cost-effective yet powerful smart camera in a micro-sized product.

The F330 offers the same machine vision software and most of the imager attributes in the F430 series, but with a different set of communication interfaces, IP rating and power specifications.

- Ultra-compact (63.0 mm x 40.0 mm x 24.1 mm)

- IP40

- Ethernet TCP/IP, EtherNet/IP, PROFINET

- Fixed focus lenses

- Integrated targeting and read/pass LED indicators. Outer LED lighting not available on this product family, but it does have the same inner LEDs (4 Red and 4 White similar to the F4xx families)

- Active Power over Ethernet (PoE)

- IEEE 802.3af PoE-compliant 36 to 57 VDC, Class 0 power input

- 500 MHz processor speed

- Suitable for machine vision inspections, measurements, presence/absence, parts location, robot guidance, OCR, OCV, Code reading and even Code verification

- Can be programmed via AutoVISION software for simpler yet powerful machine vision applications or via Visionscape programming software for more advanced applications

- Web-browser monitoring capability via Web Monitor (former CloudLink)

- Non-linear calibration (NLC) added to the new MicroHAWK family. NLC greatly improves the MicroHAWK measurement and locator capability by a factor of 20 and uses real world units, not just pixels. It turns the MicroHAWK into a precision measurement camera and cancels out lens distortion allowing users to compensate for lens distortion and perform precise measurements

- Field upgradable licenses

- Broad offering of cabling, power supply, and optical accessories

The MicroHAWK® family of barcode readers offers the most versatile decoding power available. Built on the highest-performance imaging engine in its class, MicroHAWK readers offer an array of modular hardware options to take on any decoding task in four micro form factors.

More Information

Related Story

The Fundamentals of Machine Vision in Automation: What You Need to Know

Machine vision has a place in many industries, including food & beverage, automotive, semiconductor, life sciences, and more. In this article, Ryan Marti, Product Manager – Industrial Cameras at Omron Automation walks us through the fundamentals of machine vision in automated processes and holds a lens to look at Omron’s products and solutions that are relevant to any of these industries.