Videos

-

Pilz Products & Systems Overview

June 24, 2025

Pilz products and systems are used worldwide. They offer ranges from sensor technology to control and drive technology. They track their origins to control technology, as they have pioneered PLC control systems and were one of the first suppliers worldwide. Today they are automation specialists who are committed to safety.

You do not want to make compromises in the automation of your machine or system? Their innovative and proven solutions will help you reach your goal! Pilz products and systems are now used worldwide. Their offer ranges from sensor technology to control and drive technology.

More Information

Check out their Product Overview

Related Story

Training Courses on Plant and Machinery Safety from Pilz

Plant safety is vitally important for the safe operation of technical plants. As a machine manufacturer or operator you are legally obliged to ensure the safety of plant, machinery and devices. Training courses teaches you to identify risks and avoid accidents. Further training for safety officers and employees is the key to success here. With this knowledge you can operate plants more efficiently and safely carry out maintenance work. By integrating plant safety into your company you are demonstrating responsibility and increasing the confidence of authorities, employees and the public. Plant safety also contributes towards the prevention of environmental pollution and damage.

Pilz offers a comprehensive range of further training on specialist knowledge for normative and legal requirements in Machinery Safety – from functional safety to Industrial Security. They also offer training on products and technologies in relevant sectors of automation technology for practical professional application of Pilz product solutions.

-

SNAP IN – Weidmüller Explains How to SNAP INto the Future

June 24, 2025

SNAP IN – The fastest and most secure connection technology on the market. Weidmüller shows you the numerous advantages of the new connection technology, invented by Weidmüller. Simply. Fast. Secure. Ready to Robot. When do you SNAP INto the future?

With SNAP IN, installation and maintenance work can be performed as quickly as snapping your fingers. The new connection is as simple in principle as it is to use: the stripped conductor is plugged directly into open connection points and the snap connection snaps into place with a click. And it‘s just as fast the other way round. By simply activating the lever, the operator can open the connection point again and remove the connected conductor.

More Information

Related Story

Weidmuller Canada Unveils a New Customer Experience Centre and Introduces the Innovative WOW Van for the Eastern Canada Markets

Weidmuller Canada proudly opens its new Customer Experience Centre at its headquarters in Markham, Ontario on September 12, 2024. This state-of-the-art 600 sq. ft. facility is designed to provide customers and distribution partners with an immersive, hands-on experience of Weidmuller’s latest products and solutions.

Kevin Blair, National Sales Manager at Weidmuller Canada, expressed his excitement: “We are thrilled to offer this dedicated space. Our sales representatives can now invite customers into our facility to explore the extensive range of our offerings, particularly our Wire Processing Centre and Printers. It has been challenging to convey the true value of these products without demonstrating them in person. Now, it’s much easier.”

Vice President, Jenny Raguimov added, “For customers in remote locations, we introduce the WOW (Weidmuller-On-Wheels) Van. As the name suggests, it brings Weidmuller products directly to our customers. We recognize that many of our clients are stationed at plant sites, and it’s crucial for them to see, touch, and interact with our products firsthand.”

-

ABB Energy Transition – The Power to Adapt

June 20, 2025

The ways we generate, store and distribute electrical power are changing. This once-in-a lifetime energy transition demands new technology and new ways of thinking to address a rapidly evolving grid.

ABB partners with businesses to adapt and navigate these changes by ensuring a reliable flow of electricity, and with their next-generation sulfur hexafluoride free (SF6-free) medium voltage switchgear portfolio, they support utilities and industries on their journey to more sustainable energy sources.

More Information

Related Story

The Time is Now: An Industrial Energy Efficiency Action Plan

In a whitepaper released on June third, ABB has set out the scale of the challenge facing the global industrial sector and emphasizes the critical role of industrial energy efficiency in meeting rising energy demand while strengthening energy security & affordability and driving industrial competitiveness. With 45% of the world’s electricity converted by industrial electric motors into motion1, industrial energy efficiency is a part of the solution that cannot be overlooked.

-

Airship Hangar | Essen-Mülheim Airport | SEW-EURODRIVE

June 15, 2025

Engineering Meets Architecture: The New Airship Hangar at Essen-Mülheim Airport

Measuring 92 by 42 meters and standing 26 meters tall, the new airship hangar for Westdeutsche Luftwerbung (WDL) is an architectural and technical landmark – built almost entirely from wood. Designed from the outset as both a functional airship base and a versatile event venue, the structure features a striking centerpiece: its massive gates.

Each of the two 72-ton gate wings of the airship hangar is powered by precise drive technology from SEW-EURODRIVE, implemented by automation experts INperfektion. Using powerful planetary gearmotors from SEW’s P2 series and coordinated control systems, the gates can be safely and efficiently operated – even in strong winds or snow.

Built using predominantly renewable and recyclable materials, the hangar has received both the Gold certification from the German Sustainable Building Council (DGNB) and the North Rhine-Westphalia Architecture Award.

Whether housing two airships or welcoming 1,500 guests, this structure is a unique blend of engineering excellence, sustainability, and architectural design.

More Information

Related Story

SEW-EURODRIVE Canada Secures New Location for Canadian Headquarters

SEW-EURODRIVE’s commitment to exceptional service is what got them here. For over 50 years, they have been providing top-tier drive system solutions to Canadian businesses—helping not only their own company grow but their customers as well.

-

Electric Automation Test Bench from Festo

June 6, 2025

Electric Automation Test Bench from Festo

Get Hands-On with Key Electric Automation Technologies from Festo! The Electric Automation Test Bench is a portable and convenient solution for learning, demonstrating, testing, validating, and integrating electric automation components from Festo. Designed for system integrators and industrial users, it provides a versatile platform to train on Festo products while reducing the technological risks associated with integrating new electric automation components.

Highlights of Festo’s electric automation test bench:

- Turnkey, ready-to-operate system

- Multi-protocol ready (EtherCAT, Profinet, EtherNet/IP, Modbus TCP)

- Easily transportable

- Ready to connect to third-party PLC

More Information

Contact services.didactic@festo.com for details.

Related Story

Festo Canada Celebrating 50 Years of Helping Make Canada an Automation Nation

The year was 1975. Newly created Festo Canada joined an industrial eco-system feeling the stirrings of accelerating technological change, a transformation that would become known as Industry 3.0. PLCs, articulated robots, computer numerical control systems were beginning to proliferate. The first US patent for Ethernet was filed that year. (That was also the year Festo launched the world’s first standard pneumatic cylinder series).

So much more was to follow, leading up to Industry 4.0 as we are experiencing today – digitalization, the Industrial internet of Things, cloud computing – and beyond, as industry begins widespread adoption of artificial intelligence and machine learning, with a growing emphasis on sustainability.

-

Circularity and Eco-Design at SEW-EURODRIVE

June 2, 2025

Circularity and Eco-design

Attractive products in all three dimensions: technical, economical and ecological

SEW-EURODRIVE has always been committed to good eco-design: Durable and efficient products, easy to repair with first-class services that extend service life, all from a modular system and worldwide. Based on their experience over the past decades, they are taking an even more systematic approach to the topic in order to continue to improve and are firmly anchoring eco-design in their processes.

More Information

Related Story

SEW-EURODRIVE – Unstoppable, Integrated, United

Since the start of SEW-EURODRIVE nearly 100 years ago, the importance of being aligned with the needs of the market and the customers it serves has remained their focus. The quality of products and a consistent and timely supply have helped make them a trusted manufacturer of gearmotors, drives, and modular systems. Their passion for technology has served them well over the years: new products designed and manufactured, the adoption and creation of technology and solutions for industry, as well as steadied expansion in the face of challenges. Driving the world is what they do.

-

Elevate Your Network Resilience with Moxa’s EDS-4000/G4000 Series

June 2, 2025

Discover the power of Enhanced Security, High Performance, and Unyielding Reliability with Moxa’s cutting-edge switches. These solutions are your pathway to a futureproof network—designed to meet the evolving demands of today’s industrial automation landscape. Embrace the future with confidence and build stronger, more resilient connections.

More Information

Moxa’s Layer 2 managed switches

Related Story

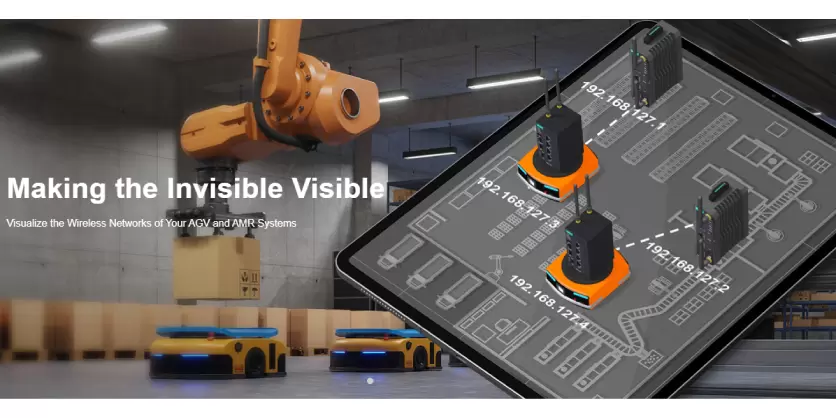

Visualize the Wireless Networks of Your AGV and AMR Systems with MOXA Solutions

As the demand for automated material handling (AMH) systems continues to rise—driven by the expansion of e-commerce and smart factories—the importance of stable wireless networks in autonomous mobile robots (AMRs) and automated guided vehicles (AGVs) has never been more significant. With AMRs projected to grow at a CAGR of 43%* and AGVs at 24%* from 2022 to 2027, uninterrupted operations for these mission-critical systems are paramount.

-

Panduit Expands Broadband Fiber to the Home

May 30, 2025

With Panduit Fiber to the Home solutions, including pedestals, fiber drop cable assemblies, and multi-port service terminals, you can have confidence in your outside plant network.

Panduit offers an expansive Outside Plant Portfolio including fiber to the home that supports last mile network connectivity required to provide access from closest serving nodes to end user locations.

Inclusive of Multiport Service Terminal (MST), Outdoor Fiber Pedestals, and Fiber Drop Cable Assemblies, this solution is tailored for residential and commercial settings where fast and stable internet service is a must.

More Information

Related Story

Panduit Boosts PDU Offerings with Worldwide Release of G6 Series

Panduit, a global leader in innovative electrical and network infrastructure solutions, is pleased to announce the global release of its G6 PDU Series. The innovative G6 line marries the best-in-class form factor of the G5 Series with an upgraded intelligence card to bring faster performance along with new functions and cybersecurity improvements to customers.

-

RS – Supporting Your Business from End-to-End

May 28, 2025

RS – supporting your business from end-to-end. From procurement solutions to inventory management, maintenance to health and safety, RS UK and Ireland are here to help your business thrive. They’ve got the products and solutions to help you focus on what matters.

Get in touch, and see how they can make your processes more efficient and cost effective today:

Related Story

RS – and IMI Make Pneumatic Motion Control Quick, Easy, and Economical

Their portfolio of IMI pneumatic actuators for industrial and process automation applications includes IMI Bimba Original Line® cylinders, which are quick, easy, and economical to replace and offer more sizes and options than comparable solutions.

-

The Smart QO Panel Solution | 90 Sec | Schneider Electric

May 20, 2025

The Smart QO Panel Solution from Schneider Electric. The simple path to automation, monitoring, and control at the circuit level where and when you need it.

More Information

Related Story

Schneider Electric Delivers Energy Management Products and Solutions in Canada

Canada is undergoing an energy transition to become more sustainable, reduce emissions, and reach net zero targets. Wiser Energy from Schneider Electric is an integral Energy Management System that monitors devices and energy usage in real-time, helping you use electrical energy more wisely in your building.