Schunk: SPS 2019 – Digitalization of gripping

October 28, 2019

Two fundamental development directions are currently discernible: On the one hand, the trend towards simplification, i.e. an easy introduction to robotics and intuitive operation of robots and assembly systems. On the other hand there is the trend towards smart solutions: More and more functions, sensors and intelligence are being integrated directly into gripper system components. “Tomorrow’s gripping systems can be intuitively programmed, and flexibly used. They monitor the production process and can increasingly be operated autonomously,” says the CEO of SCHUNK GmbH & Co. KG from Lauffen am Neckar.

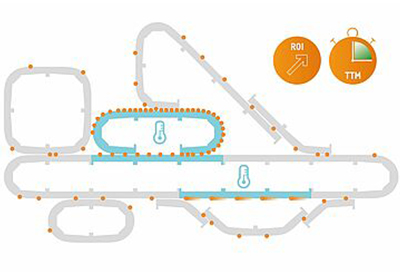

SCHUNK’s digitalization strategy does not end with the pure component. Rather, the company spans a digital overall framework from the calculation and design tool via digital twins for design and simulation to commissioning and the ongoing process. Using the example of the intelligent PROFINET small components gripper EGI, SCHUNK will present at the SPS how such digital integration can be successful and what advantages are associated with it. Also included: a smart long-stroke gripper with Plug & Work interface for the lightweight robots from Universal Robots, an intelligent rotary module and co-act grippers for collaborative applications.

“Digital technology and artificial intelligence methods will revolutionize assembly and handling over the coming years,” Henrik A. Schunk stresses during the run-up to SPS 2019.