Intelligent Cooling Opens up New Potential

November 3, 2020

Improved performance with ACOPOStrak cooling system

Motor segments for the intelligent ACOPOStrak system are now also available with built-in liquid cooling. This further expands the track’s performance spectrum. Integrated directly in each motor segment, the cooling system requires no additional installation.

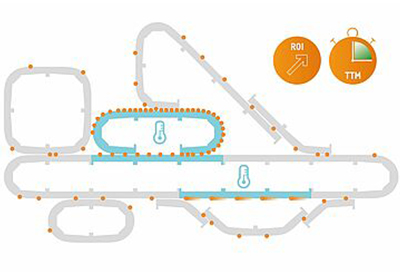

The new motor segments can be used to cool specific sections of track that need it most. In highly dynamic applications, large numbers of shuttles accelerate and brake on certain track segments. The resulting heat is absorbed by the liquid cooling system and transported away via a cooling medium that is pumped through the cooling circuit.

Thermal calculations made easy

The mapp Trak system software calculates exactly where the track system has the highest power requirements. From this information, it is able to determine how much heat will be generated in each track segment. The software’s simulation indicates which parts of the track require cooled motor segments. Track segments can be connected in series, in parallel or a combination of the two. The ability to limit cooling to where it is actually needed makes the ACOPOStrak cooling system particularly cost effective. It adapts flexibly to any application without any additional hardware testing, ensuring the maximum benefit for the user.