OMNI CT and ABB To Collaborate On Innovative Waste-To-Fuel Technology

October 27, 2022

ABB’s automation and electrical technology will enhance operational efficiency of OMNI CT’s state-of-the-art waste refining system. Companies will collaborate on a combined offering that turns waste into synthetic gas and other fuels, supporting municipal and industrial companies as they strive for a more sustainable future.

ABB received a Letter of Award from Canadian cleantech company OMNI Conversion Technologies Inc. (OMNI CT) to offer municipalities and industry a fully integrated waste-to-energy solution. ABB was selected by OMNI CT to provide cutting-edge automation technologies to support their process, including industry-leading distributed control system ABB Ability™ System 800xA and ABB integrated eHouse solutions, ready to operate in the field with minimal installation, commissioning, and start-up time. The ABB Ability™ System 800xA is not only a distributed control system (DCS) it’s also an electrical control system, a safety system, and a collaboration enabler with the capacity to improve engineering efficiency, operator performance and asset utilization.

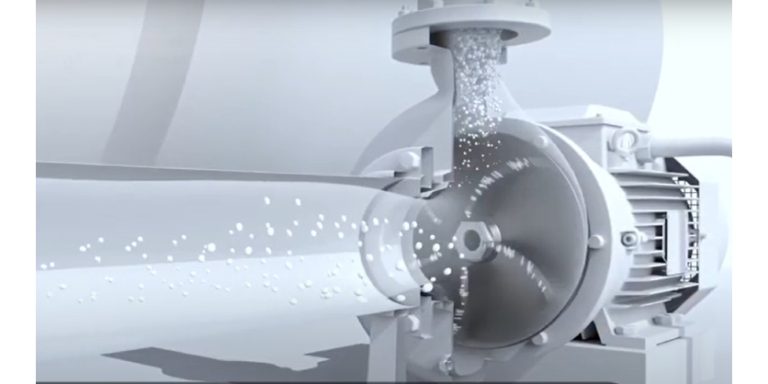

OMNI CT’s patented OMNI200™ Gasification & Plasma Refining System can take virtually any energetic solid material – from black-bagged municipal garbage to industrial and commercial waste, to residual biomass – and turn it into synthetic gas (syngas) through a thermal conversion process. Syngas can be used as a substitute for natural gas or can be converted to hydrogen, synthetic natural gas, chemicals, liquid fuels, or electricity for use in a wide range of industries.

OMNI CT’s technology will be fortified by ABB’s experience in integrated electrical and automation solutions for energy industries.

“The Omni200™ technology, proven at industrial scale, is a completely integrated system, delivered to site and installed by OMNI. This system processes 200 tons of feedstock per day into clean consistent syngas,” said Marc Bacon, President and COO, OMNI Conversion Technologies Inc. “We selected ABB based on their engineering capabilities, their local and global support network and innovative solution. ABB’s unique portfolio of integrated automation, electrical and digital solutions ensure a secure, reliable, and steady electrical power supply to our system.”

“The collaboration underlines a shared focus on reducing carbon emissions and driving decarbonization. We are thrilled that OMNI CT selected ABB as their supplier of choice for integrated electrical and automation solutions for their Omni200™ product,” said Ben Venter, Vice President, ABB Energy Industries, Canada. “Sustainability is embedded in everything we do at ABB. We are excited to partner with OMNI CT to advance clean energy technology. Apart from customers becoming more sustainable, our technology will also help them to continually improve productivity and run safer operations.”