Tackling Costly Cavitation Challenges with The Anti-Cavitation Solution in ABB Drives

Cavitation causes damage to pump and pumping systems which increases maintenance costs. It can also destroy the product, resulting in lost revenue. In industries such as food and beverage and water treatment pumps are used to move liquids from one point to another

January 16, 2023

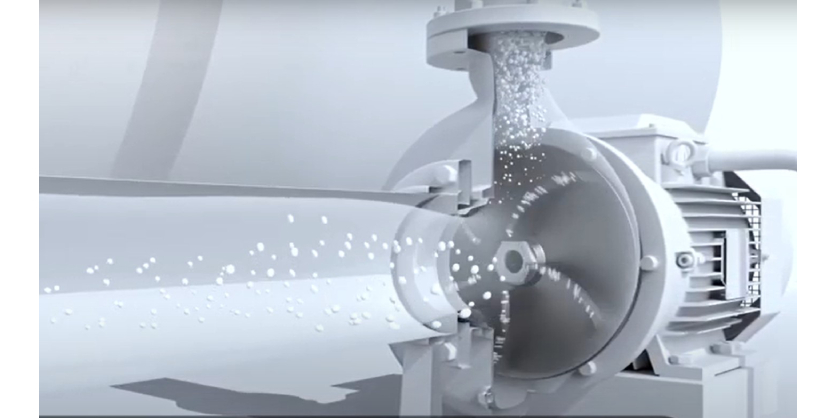

Cavitation can occur when the inlet pressure of the liquid to the pump is low. This can be due to low level of liquid in a tank or a pipe with an almost closed valve that supplies the liquid to the pumping system. Cavitation is the formation and subsequent collapse of vapor bubbles inside the liquid sending shockwaves through the pump and pipes. The implosion of a bubble leads to surface erosion of pump impellers, pump housing and pipes. In dairies and other beverage production facilities, cavitation lowers the quality of the product, such as milk, which can increase costs. Cavitation is destructive for centrifugal pumps.

The innovative anti-cavitation solution in ABB drives

ABB has solved the challenge of cavitation with the innovative anti-cavitation feature found in ACQ580 water and wastewater drives, ACS580 general machinery drives and ACS880 industrial drives. The ABB anti-cavitation feature is accurate and cost effective as it does not require external sensors to be connected to the drive. In addition, ABB drives offer a range of additional features and benefits for ensuring reliable and energy efficient pumping and operation.

ABB drives offering anti-cavitation solutions

General purpose drives

Get it fast. Use it easily. Improve your processes. Take charge of control and energy saving. Enjoy the plug and play motor control convenience, straight from the box. When you are looking for simplicity and intelligence in a self-contained solution, general-purpose drives cover your options wisely. Wherever your business needs are, our globally renowned reliability and service easily matches your requirements. The all-compatible general-purpose drives are designed to control a wide range of applications such as mixers, conveyors, compressors, fans, pumps, centrifuges, as well as process control in industries including material handling, food and beverage, chemical, rubber and plastics, textile and printing. The drives are easy to select, install, configure and use, saving considerable time.

ABB’s general purpose drives offer you:

- Drives with all the essential features built-in, simplifying drive selection, installation and use.

- Intuitive user interfaces for quick drive setup and commissioning.

- Built-in features for energy efficiency helping you save and manage energy.

- Wide availability via ABB’s value provider network.

Industrial drives

Simplicity and compatibility for all your industrial drive needs. With the ACS880 single drives you simplify your world and open all possibilities. You have complete flexibility and capability in wall-mounted or cabinet-built drives. All can be customized to your precise needs in industries such as oil and gas, mining, metals, chemicals, cement, power plants, material handling, pulp and paper, sawmills and marine. Built on ABB’s common drive platform for precision control in a wide range of applications such as cranes, extruders, winches, winders, conveyors, mixers, compressors, pumps and fans.

Highlights:

- Intuitive control panel and PC tool

- Direct torque control (DTC) for precise open and closed loop control

- Built-in safety features for simplified configuration

- Communication with all major automation networks

- Removable memory unit for easy drive commissioning and replacement

- Energy optimizer and energy efficiency information for monitoring and saving energy

- Designed for easy service

Water and wastewater drives

Robust design securing optimal flow of water and wastewater. The all-compatible ACQ580 drives for water and wastewater simplify your pumping processes and motor control while ensuring energy efficiency. These robust and compact wall-mounted, module and cabinet-built drives have built-in pumping functionalities such as sensorless flow calculation, multipump control, level control, soft pipe fill, dry run protection, quick ramps and pump cleaning. Usability is enhanced with the intuitive Hand-Off-Auto control panel and the PC tool Drive composer. The built-in energy calculator visualizes the energy savings achieved with the drive. The ACQ580 controls virtually any kind of motor including IE5 synchronous reluctance motors. Connectivity is supported by a wide range of fieldbus protocols.

The ACQ580 also offers an ultra-low harmonic variant ensuring stable and smooth power network during water treatment and operation:

- 0.75 to 500 kW, 380 to 480 V

- IP00, IP20, IP21, IP42, IP54 and IP55 enclosure classes allow installation on walls, into cabinets and as free standing drive modules

- Built-in energy saving calulator and pump functionalities secure optimal pump operation

- Supports IE5 synchronous reluctance, asynchronous induction and permanent magnet motors

- Connects to a wide range of water and wastewater control systems

- Our local partners provide wide availability of service and support

- Online ABB SmartGuides – the opportunity to swipe and get help with commissioning and programming

Cavitation detection and control for industries

ABB drives for dairy solutions

Dairy automation. Producing the finest quality dairy products is the goal. With so many processes involved in processing raw milk, you need every bit of capability that automation can give you to ensure milk, yogurt, cream, butter, cheese and ice cream leaves your dairy efficiently, all while meeting the strictest hygiene requirements.

Dairy processes heavily use pumps, mixers and separators. Our automation offering includes a wide range of variable speed drives, high-efficiency and wash down type of motors, scalable Programmable logic controllers (PLC) and a selection of HMIs capable of handling all your processes smoothly and efficiently. Additionally, safety functions, from built-in safe torque off to a wide range of optional safety functions gives you the flexibility to meet your safety requirements. PLCs can deliver integrated control systems that help to provide enhanced visibility and control over the processes within dairy production and processing.

From production and pasteurization to storing and cleaning, our automation solutions provide you the control and flexibility for energy efficient, reliable production.

Using proper cavitation detection and control reduces the need of maintenance of pumps and pipes. It also lowers the risk of destroyed products like milk which minimizes lost revenue. The Innovative ABB anti-cavitation feature built inside ABB drives (ACS580 general purpose drives and ACS880 industrial drives) help mitigate cavitation in pumps and pipes. The solution is accurate and cost effective as it does not require any external sensors to be added to the drive. Energy efficiency. Flexibility. Control and cleanliness. Everything counts when producing quality dairy products.

ABB drives for brewery solutions

Brewery automation. You face so many daily challenges to meet all the parameters your brewery needs. There are no short cuts to the perfect brew, and that’s why we developed our automation offering to help you control each of the many processes simply, consistently and efficiently. With so many processes included in your brewery, you face a daily challenge of managing energy and water consumption, and maintaining hygiene.

ABB’s variable speed drives, PLCs and HMIs make it easy for you to sync your parameters with your processes for the most hygienic and efficient operations. ABB’s automation offering includes safety function options, from built-in safe torque off to safety PLCs, you can implement the safety functions to meet your specific needs. All with worldwide support and service.

Using proper cavitation detection and control reduces the need for maintenance of pumps and pipes. It also lowers the risk of destroyed products like beer which minimizes lost revenue. The Innovative ABB anti-cavitation feature built inside ABB drives (ACS580 general purpose drives and ACS880 industrial drives) help mitigate cavitation in pumps and pipes. The solution is accurate and cost effective as it does not require any external sensors to be added to the drive.Precision. Energy efficiency. Flexibility. Everything counts.

ABB drives for water and wastewater solutions

Pumping up your water performance. ABB offers a range of efficient water solutions to control and optimize the pumping of clean water. From energy-efficient motors to variable speed drives that optimize pump operations and eliminate the risk of pump failure or leakages. If your system uses throttling to control the flow rate of water, you can save a lot of energy by upgrading your pump control to a ABB variable speed drive instead.

ABB drives and motors are designed for harsh environments to with stand corrosive and wet conditions. The water dedicated drives speak the language of the pump operator making them easy to use. To ensure 24/7 flow of water ABB offers local support and service, including ABB Ability™ Condition Monitoring for improving pump operations and preventing future pump failures. Our PLC’s connect seamlessly with ABB variable speed drives for efficient and accurate water treatment operations.