Cost Saving with VFD and its built-in PLC (SoftPLC)

August 29, 2019

By Elmir Rahimpour, Former Automation & Integration Specialist, WEG Canada

In conventional applications, pumps or fan should be run at full speed, then pressure or flow should be controlled with a control valves hence some energy will be wasted when you throttling control valves. One of the major usages of VFD is cost saving through energy saving.

But we want to look from different angle of cost saving which is capital saving through removing some instrumentation and control valves and utilize VFD with built-in PLC.

If you can replace one VFD with built-in PLC, you can remove control valve, independent PLC for throttling, additional sensors/ transmitters for motor speed, torque, flow element / transmitters, cabling, Junction boxes, installation stands for the transmitters and sensor.

In addition, some other parameters such as motor speed, motor torque, motor current which are freely available when SoftPLC code is used.

In addition, some other parameters such as motor speed, motor torque, motor current which are freely available when SoftPLC code is used.

There is a SIL2 IEC 61508 STO relays that can stop VFD in case of requirement for Shutdown command, from safety sensors such as vibration protection system.flow element / transmitters, cabling, Junction boxes, installation stands for the transmitters and sensor. In addition, some other parameters such as motor speed, motor torque, motor current which are freely available when SoftPLC code is used.speed, motor torque, motor current which are freely available when SoftPLC code is used.

Below are few applications that can utilize built-in SoftPLC with VFD solution:

Header pressure control with Multi Pump Control:

In traditional method, N+1 pump will be connected to the same header, and header pressure to be controlled with control valve downstream of header or flow control valve on each individual pump discharge. In addition, zero or no-flow sensor (transmitter or switch) at down stream of each pump required, as well as pressure monitoring of upstream and down stream of each pump. Flow or pressure will protect the pump by tripping the pump on PAHH, FALL or PALL.

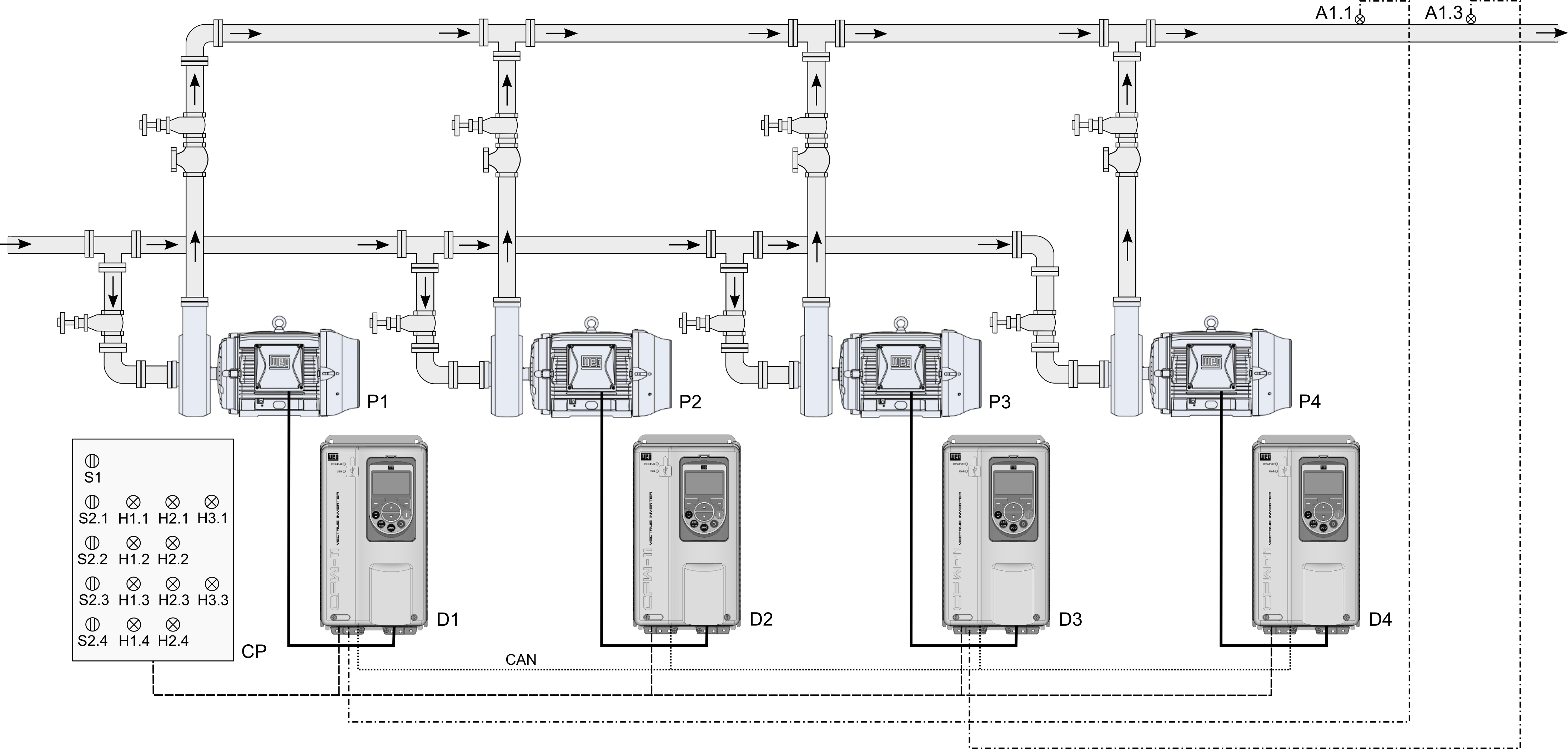

It can be done with one or more VFD, as per below schematic diagram:

Pump Genius Multiplex application for four pumps in parallel controlled by CAN communication interface

For zero flow control, you just need to set a protection in SoftPLC code if the torque percentage is less than a value (e.g. 20%) and motor is at certain speed. All of the auxiliary pumps such as lube oil pump can be programmed in VFC softPLC. Hence costly control valves, flow transmitters can be removed and the same for additional hook-up, cables, JB, tray, etc.

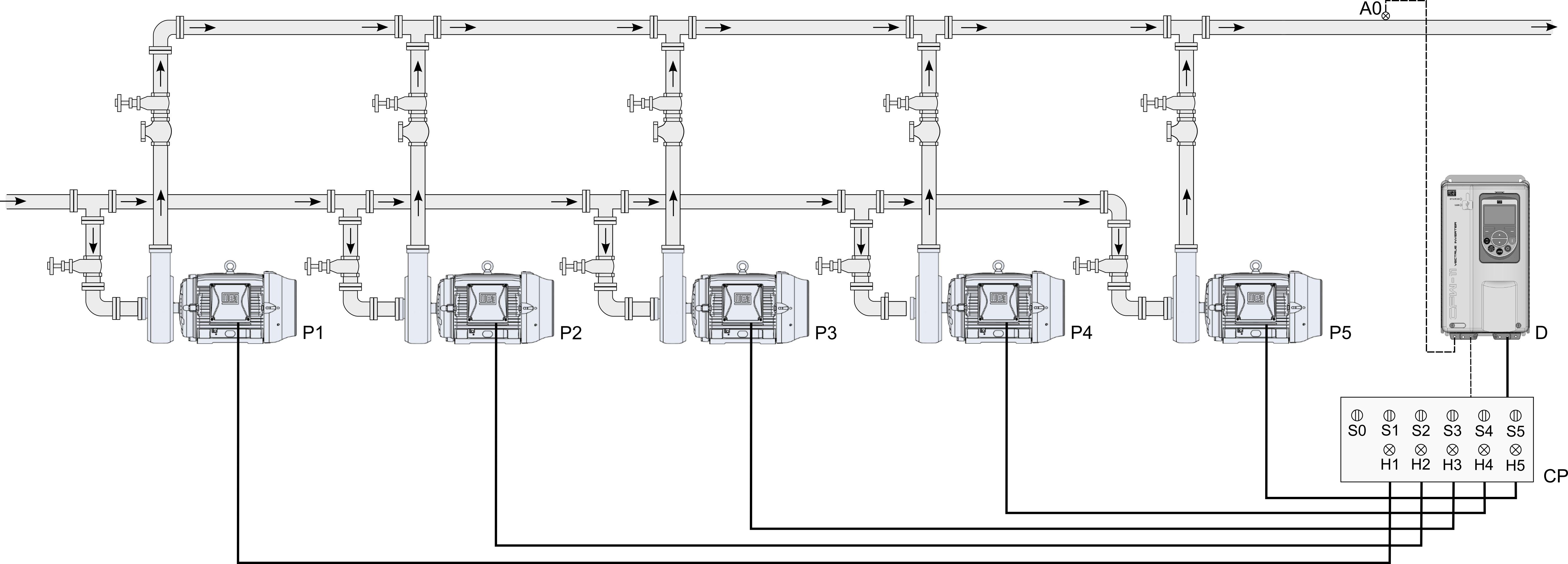

Pump Genius Multipump floating control for five pumps in parallel

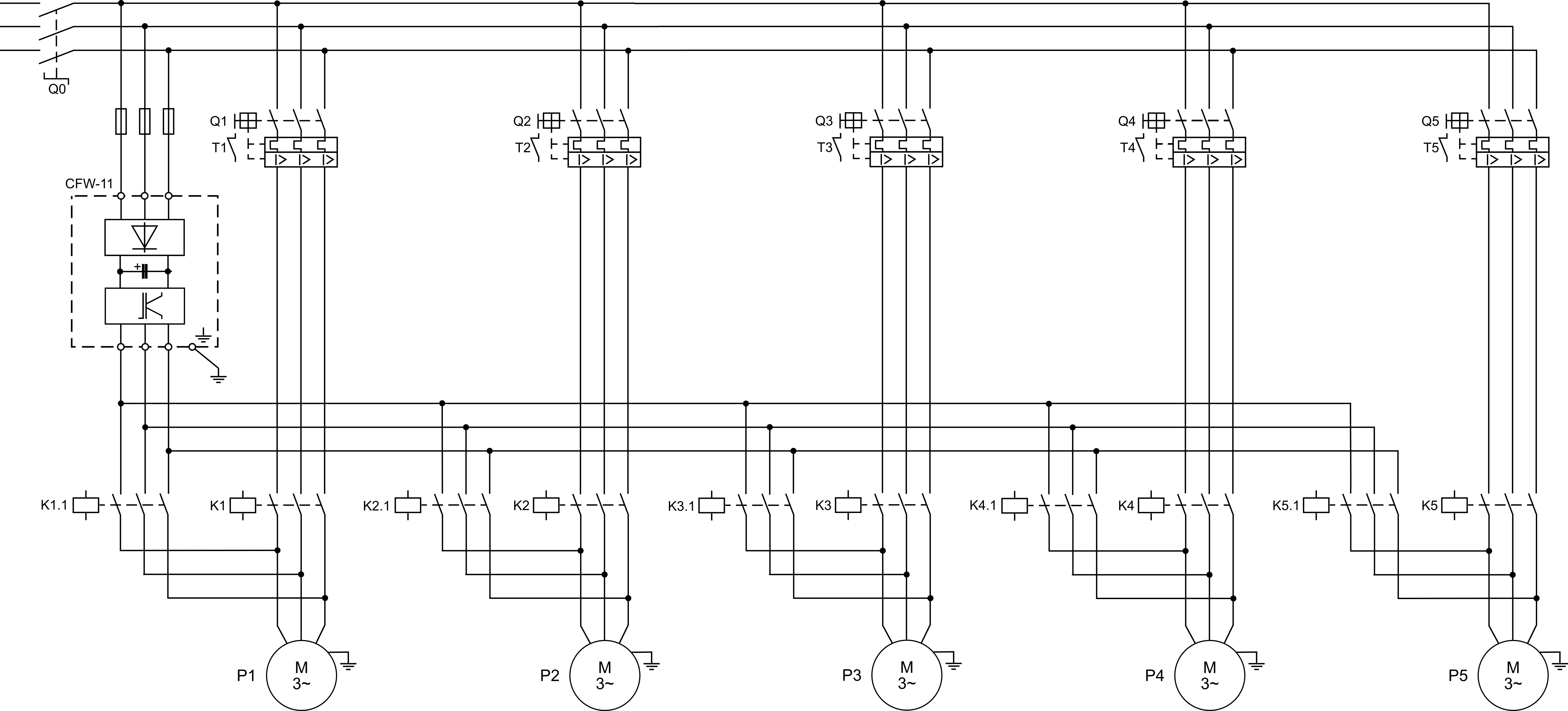

Power connection of the Pump Genius Multipump floating control for five pumps in parallel

Control of air flow/ pressure with Fan

If built-in SoftPLC with VFD is used, you can connect the pressure or flow sensor to VFD and set internal PID controller to control the fan speed with respect to the the set pressure or flow rate. As VFD has DI, AI, you can have a lots of interlocks for safety and similar to pump application, you can detect the fault with the internal parameters of VFD which could be more effective in compare to some vibration protection sensors.

Differential pressure of filters can be connected to VFD with SoftPLC and get respective alarm or fault trip as required.set pressure or flow rate. As VFD has DI, AI, you can have a lots of interlocks for safety and similar to pump application, you can detect the fault with the internal parameters of VFD which could be more effective in compare to some vibration protection sensors.Traditionally, damper can be used for air flow or pressure control, and for fan protection you should be using the vibration sensor and run the fan on full speed.

This paper was prepared by Elmir Rahimpour, former WEG Canada Automation Specialist and presented at 2019 ISA Calgary Show – Knowledge Hub on April 9, 2019 by Ankit Sharma, WEG Canada Business Development Manager. Missed the WEG Canada Cost Saving Seminar? You will like to learn more on how to increase productive while reducing energy cost by removing some instrumentation and control valves and by utilizing VFD with built-in PLC? Register to the upcoming Webseries on Cost Saving with WEG VFD & its built-in PLC (soft PLC); hosted by WEG Canada Automation experts & special guests! Coming soon this Fall! Please click here to RSVP to the upcoming Cost Savings Webisodes & Podcast! * Please RSVP – limited spots available.

About WEG Canada / V.J. Pamensky

WEG is acknowledged today as one of the largest manufacturers of electric motors, controls and transformers in the world. WEG provides complete industrial automation solutions using the most modern hardware and software tools available in the market.Delivering to many renowned companies, we call special attention to the supply of automation systems for applications in Siderurgy (Laminators), Energy (Substations and Energy Co-generation Systems), Food, Pulp and Paper (Paper Machines), Civil Construction (Intelligent Buildings), Water and Sanitation (Sewage System and Water Pumping) and Ports.An accentuated trend in the past few years, communication networks allow fast exchange of information. These programmable controllers allow information exchanges in various communication protocols, like Profibus, DeviceNet, ModBus, among others.

V.J. Pamensky Canada Inc. was founded in Toronto, Ontario in September 1977 as the exclusive importer of WEG Electric Motors, Controls and Transformers into Canada. The original inventory was small, as were the premises, but these products quickly found a place in the Canadian industrial market. From these beginnings, growth came rapidly, resulting in successive moves to different locations in order to meet the demands for increased inventory and service.Today, V.J. Pamensky Canada Inc. is one of the largest importers of electric motors and controls in Canada with offices and warehouses across the country. V.J. Pamensky Canada Inc. has probably the largest inventory of any Electric Motor and Control Company in Canada. V.J. Pamensky Canada Inc. offers 24 hour emergency service, and will customize and modify products to meet the Customer’s most demanding specifications.

Visit WEG Canada