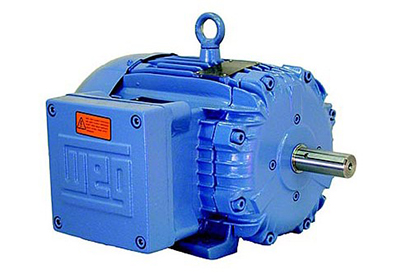

Weg: Explosion Proof Motors – NEMA Premium Efficiency

November 29, 2019

WEG Explosion Proof motors are suitable for applications requiring UL or CSA certification for hazardous locations. Thermally protected with thermostats, all motors manufactured are submitted to hydrostatic as well as other routine testing at the factory to ensure compliance to the required specifications. WEG NEMA Premium Efficiency Explosion Proof motors are specifically designed to meet or exceed all EPAct requirements for energy efficiency.

Standard Features

- – Efficiency Certification number EEV 78282 according to National Resources Canada (NRCan) – CSA C390

- – Efficiency Certification number CC029A according to US Department of Energy Regulations

- – Three-phase, 2, 4, 6 & 8 pole, 60 & 50 Hz

- – Voltage: 230/460, 460 or 575V

- – Totally Enclosed Fan Cooled – (IP55)

- – Squirrel cage rotor / Aluminum die cast

- – Class ‘F’ insulation

- – 104°F (40ºC) ambient temperature

- – Temperature rise: Class ‘B’ (80ºC)

- – Altitude: 3300 ft (1000 m)

- – NEMA ratings design ‘B’

- – 1045 heat treated and stress relieved carbon steel shaft up to 365T. 4140 for frame 404T and up

- – Continuous Duty (S1)

- – NEMA dimensions

- – Non-sparking fan

- – Service factor: 1.15

- – Stainless steel nameplate

- – Thermostats

- – F1 mount

- – NPT threaded terminal box conduit hole

- – Color: RAL 5009 – (Blue)

- – WEG paint plan 201A

- – Regreasable bearings, positive pressure lubrication system (frames 364T and up)

Optional Features

- – C and D flanges available for all frames

- – F2 mount

- – Special Voltages and frequency

- – Stainless steel shaft

- – IP56

- – Washdown Duty

Temp Code T4

- – CSA / UL: Class I – Division 1 – Groups C and D

- – CSA: Class II – Division 1 – Groups F and G

- – CSA: Class I, Zone 1, IIB

Inverter Duty

- – Inverter Duty Certified for 20:1 CT & 1000:1 VT *

- – Inverter Duty Certified for 1000:1 CT with a WEG VFD running in Optimized Flux mode

- – Inverter Duty CSA certified for Division 1, Class I, Groups C & D and Division 1, Class II, Groups F & G

* 449T and 586/7T frame sizes not included. Other speed ranges available. Call for specific ratings

Applications

- – Petroleum and gasoline

- – Flour / feed mills

- – Grain elevators

- – Fans

- – Pumps

- – Blowers

- – Material handling equipment

- – Other applications requiring motors UL or CSA listed for hazardous locations