Saving the Planet, and Money

Saving the Planet, and Money, with the Affinity Law for Pumps and Fans

January 12, 2023

Reducing energy, this has been and will continue to be a hot topic in Canada. There are many ways to do this, the best of course is to not use power but we all know that this can’t happen as the word keeps turning.

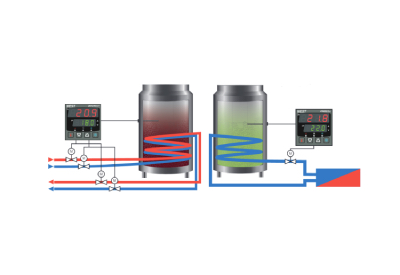

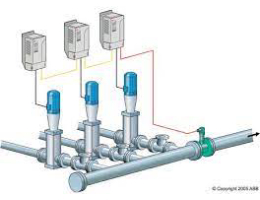

One very successful option to reduce your power consumption is with centrifugal pump and fan applications. If you are still using dampers, bypasses or throttling valves to control your system you simply utilize a drive / VFD like ABB’s ACQ580. Add a feedback device like a pressure transducer, flow sensor or building automation system to control and reduce the motor speed when possible based on system requirements.

In these systems the “Affinity Law” states if a pump / fan speed is changed, flow rate is directly proportional to the speed, whereas the head / flow is directly proportional to the square of the speed. In plain terms a reduction in speed by “x” percent reduces the flow equally while reducing the required power which is a cube of the driven speed.

See here a quick example of the affinity law using ABB’s online ABB Energy Save Calculator of a 50Hp pump if switched from a throttling valve to VFD control on a standard bell curve running 24 /7 that will save you $14350.00 a year !

Take a look at the pumps and fans in your facility, then see the chart to see the effective power savings and also the reduction in your power consumption and lowered utility bill ! The larger the motor the more money you can save .

Related Story

Ultra-Low Harmonic Drives for Increased Efficiency and Reliability of Processes and Systems