Glycol Chiller & Heater Solutions for the Wine-Making Industry

November 22, 2022

One of the most important factors in making wine is fermentation. The rate of fermentation can impact the flavors of the resulting wine. This rate can be manipulated by controlling the temperature during the fermentation process to achieve the desired flavor characteristics.

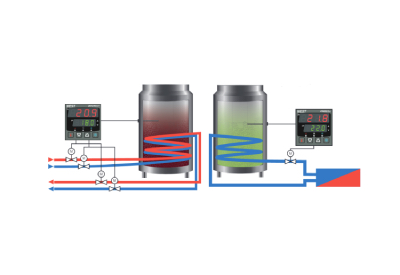

The way winemakers do this is with the use of a glycol chiller or a chiller/heater. Glycol can be chilled below 0°C (32°F). This makes it very effective for cooling, but you will need to maintain and control a temperature higher than freezing by adjusting the flow rate of the glycol through the heat exchanger.

The range of temperatures and the duration and timing of cooling or heating are factors needing close attention to maintain flavor profiles consistently. For example, red wine can require heat early in fermentation. Typical temps are 80-90° F, and more heat can speed up the fermentation. Some prefer slightly lower temperatures with red wines to extend the fermentation or to give the wines a more fruity flavor. White wine’s fermentation temperatures are much cooler, usually over 10°C (50°F), and even more so with aromatic white wines.

Application Challenge:

Finding a simplified and accurate automatic temperature control solution for use with glycol chilling and heating systems designed and engineered specifically for the wine making industry.

Application Solution:

Gems Sensors & Controls Vinireg+ and Oenoreg+ temperature controllers by West. Vinireg+ and Oenoreg+ are purpose-designed controllers for the wine industry. With intuitive user operation, dedicated buttons and clear display, these controllers offer improved efficiency and more accurate temperatures. They save time, effort, and errors associated with manually opening and closing valves in glycol systems.

Features:

- •1/16 DIN (48 x 48 x 110mm) and 1/8 DIN (96 x 48 x 110mm) formats (HxWxD)

- •START/STOP of heating and cooling circuits.

- •The target temperature set on front panel

- •Single or two setpoints

- •Two control outputs for heat and cool water circuits

- •One process alarm – Deviation high or low, absolute high or low, band

- •Wine density alarm via remote signal input

Adjacent Products: