Omron Introduces the SWIR Camera Series Enabling Precision Inspection Across the Manufacturing Process Using Short Wave Infrared Technology

October 24, 2023

The new SWIR Camera Series is taking inspection opportunities to new avenues by featuring new infrared technology, versatile inspection capabilities, multiple unique interfaces, and one-of-a-kind heat dissipation technology.

Industry automation solutions provider Omron Automation introduces the new SWIR camera series that uses unique Short Wave Infrared technology to help overcome common manufacturing challenges. By utilizing this latest technology, it delivers unmatched performance in capturing images and data exceeding the capabilities of traditional cameras. The sensitivity to wavelengths beyond what the human eye can see opens doors to many applications across industries.

Manufacturers in the Food and Commodity industry struggle with ambient lighting interfering with machine vision inspections. By utilizing SWIR, vision engineers and system designers can remove the need to depend on traditional lighting and are equipped with highly controlled and precise inspection, removing variability. In the Semiconductor and Electronic industries, post manufacturing inspections require intrusive technologies. SWIR revolutionizes this process by allowing inspectors to see through different visual spectrums, facilitating inspections of concealed items, even under plastic wrap or silicon coating.

Key features of the SWIR Camera Series:

- Top of the line, high-end sensors: Sony Pregius IMX990 and IMX991 SWIR Sensors

- Unique Interfaces for Customizability: GigE Vision, USB3 Vision, Camera Link Interfaces 0.3MP or 1.3MP resolution

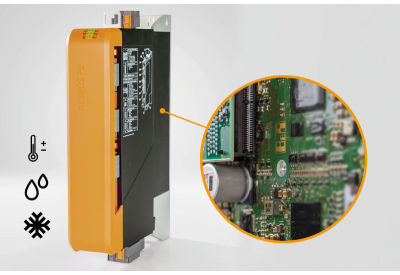

- One-of-a-kind Heat dissipation technology: Fanless Peltier Cooling Design

- Removes environmental dependency and variability: SWIR technology allows for highly controlled and precision inspection

- Inspect the impossible: SWIR technology allows inspection throughout the full manufacturing process, even under plastic wrap or silicon coating.

More Information

SWIR Camera Series with Short Wave Infrared Technology

Related Story

The Fundamentals of Machine Vision in Automation: What You Need to Know

Machine vision has a place in many industries, including food & beverage, automotive, semiconductor, life sciences, and more. In this article, Ryan Marti, Product Manager – Industrial Cameras at Omron Automation walks us through the fundamentals of machine vision in automated processes and holds a lens to look at Omron’s products and solutions that are relevant to any of these industries.