Electromate: AC PLANETARY GEARMOTORS

August 15, 2019

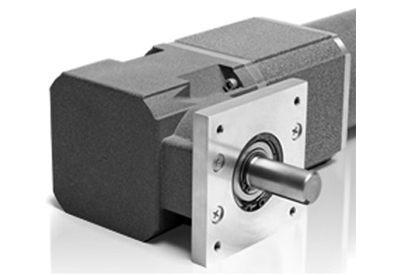

AC Gearmotors are rugged and built for demanding applications. With quiet and reliable operation, AC gearmotors combine the speed and torque of an AC motor with the benefits of parallel shaft reducers, planetary reducers, and right angle reducers, creating a compact, high torque gearmotor. This makes them a good choice for applications where high torque, continuous duty, and space are important considerations.

Characteristics of AC Gearmotors

- Relatively fixed speed operation, 3400 RPM maximum

- AC motors are constructed with class “H” insulation components allowing for running temperatures up to 180° C

- Low (single phase) to medium (three phase) starting torque

- Standard life of 20,000+ hours

- Totally enclosed construction is typical

- Class F insulation standards, withstands higher temperatures in intermittent applications

- Maintains speed over a wide range of torque

- Quiet operation

- No control required

Groshopp AC Gearmotor Features

- Parallel Shaft Versions 5:1-320:1

- Planetary Gearhead Versions 5:1-1000:1

- Right Angle Versions 5:1-100:1

- Right Angle Planetary Gearhead Versions 5:1-377:1

- Single or Three Phase Motors

- Inverter duty standard