ACOPOS P3 Defies Environmental Influences, B&R Automation

May 26, 2022

B&R servo drive now more resistant

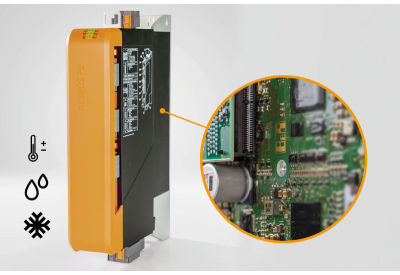

The compact B&R servo drive is suitable for use in aggressive atmospheric environments and at temperatures as low as -25°C. The electronics of the ACOPOS P3 are protected from external influences by a special coating as standard, making the servo drive even more resistant.

The servo drive can now easily be used under extreme conditions like those faced by wind turbines. Applications in cold rooms or in very dusty environments such as the textile industry are also possible. Additional expensive special hardware is no longer required, which reduces costs.

Comprehensive testing

B&R conducts extensive environmental testing to ensure the reliable performance of its hardware. The tests are carried out in a fully accredited in-house testing laboratory and in certified external testing facilities in accordance with international standards and regulations.

The electronics of the ACOPOS P3 are specially coated for use under aggressive atmospheric conditions and at temperatures as low as -25°C.

To learn. more abou the ACOPOS P3 servo drive from B&R, click here