Festo Introduces the Electric Motion Sizing Online Tool for Quick Selection of Servo Drives

Users receive a choice of perfectly dimensioned options for electric and electromechanical drive components in minutes

March 20, 2023

Festo introduces the company’s latest online productivity tool – Electric Motion Sizing – for error-free sizing of linear and rotary electromechanical systems. Electric Motion Sizing improves project efficiency by slashing the engineering time required for identifying and specifying harmonized electric motion systems. Multi-axis handling systems can be specified with Electric Motion Sizing’s sister productivity tool Handling Guide Online, which offers similar benefits.

Festo developed Electric Motion Sizing because it recognizes that machine builders need solutions that help bring products to market faster with less engineering and purchasing overhead. Electric Motion Sizing compresses hours of toil down to minutes.

With this free online productivity tool, users simply input key parameters, such as mass, stroke/travel distance, and cycle time. Electric Motion Sizing performs the complex mass moment of inertia calculations. The tool identifies in real time the combination of components most effective for the application’s parameters. Up to five optimum solutions and motor curves are presented for consideration. The specified components work together, so interoperability is not a concern. Designers can fine tune the selected system by choosing encoder type, brake, and mechanics.

Seamless integration with the Festo online shop

Following selection, the Electric Motion Sizing tool transfers the selected combination of components to the Festo online shop, together with commissioning files. The online shop provides pricing and delivery information. The seamless process from configuration to order is an additional time saver.

Integration with commissioning software

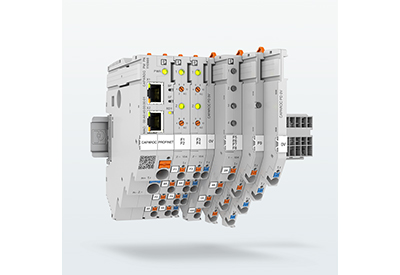

Festo integrated Electric Motion Sizing with the Festo Automation Suite for simplified commissioning. With the Festo Automation Suite, diverse products from remote IO to pneumatic valve terminals, PLCs, and servo drives are commissioned via a single free tool. Automation Suite automatically connects to the Festo cloud to download project specific documentation and updates within the software. It also incorporates Codesys code for programming PLCs and motion controllers.

More Information

Related Story

Festo Features Electric Automation Innovations at ProMat 2023

Festo is highlighting several of its latest innovations in electric automation, including its unique Simplified Motion Series (SMS) at ProMat, the North American supply chain exhibition, held this year from March 20-23 in Chicago.