ABB’s new Dodge Food Safe bearings designed for aggressive cleaning

March 11, 2019

ABB’s Dodge Food Safe ball bearings, the first to achieve IP69 and be warranted against failure due to water ingress, help maintain hygiene standards and extend equipment life.

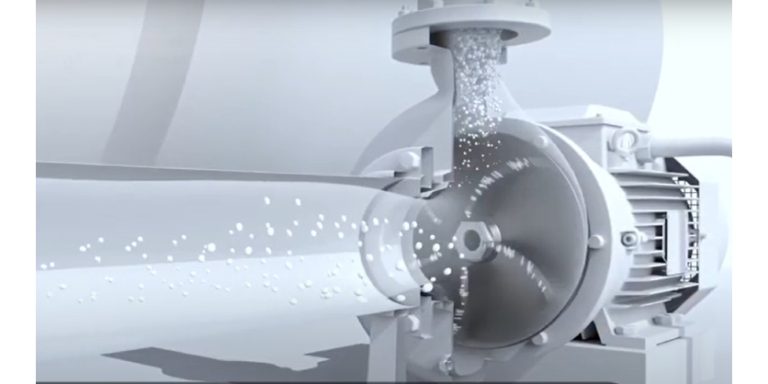

The Dodge Food Safe mounted ball bearings are designed to withstand caustic, high-pressure cleaning and sanitation processes. The new bearings are the first industrial bearings to achieve the IP69 water protection rating without the use of an end cover, making them ideal for use in the food and beverage industry, where equipment must be aggressively cleaned. They are the only bearings to carry a warranty against failure due to water ingress.

Consumers and stringent health regulations increasingly challenge food manufacturers to guarantee higher food safety and hygiene standards. However, harsh chemicals and high-pressure sprays used in clean-in-place (CIP) procedures can quickly deteriorate product reliability.

ABB’s Food Safe bearings are resilient against these cleaning agents. The bearings’ 100% stainless steel insert design combined with a revolutionary top coat, KleenTec, offers superior protection against corrosion. The smooth housing without a grease fitting minimizes contamination harbour points and is easy to clean. The bearing is sealed and lubricated for life to minimize maintenance costs.

To prevent grease wash-out, the leading cause for bearing failure in washdown environments, the Food Safe bearing is equipped with industry-leading lubrication protection. The Hydro armor sealing system, with a stainless steel flinger and four contact lip seals, prevent water and contamination from entering the bearing. ABB’s patented ball retainer, the Maxlife cage, retains a large volume of grease in compartments around the rolling elements to prevent wash-out during high pressure cleaning.

“Food Safe bearings solve the two most common reliability problems in the food industry – grease washout and corrosion,” says David Kaunitz, Dodge Mounted Ball Bearing Product Manager for ABB. “We are so confident in our design that if a customer registers their Food Safe bearings, they will receive a one-year warranty against failure due to water ingress.”

Food Safe bearings are available in a variety of housing styles, including pillow block, tapped base, flange and take-ups ranging in sizes from ½ inch (20mm) up to 1-15/16 inch (50 mm).

Go HERE for more information