ABB’s Brampton Plant Masters Customization and Adaptation to Fit the Canadian Market

May 9, 2022

Building Durable Solutions to Drive Efficiency for Canadian Customers

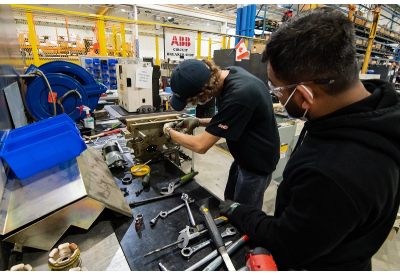

Whether it’s lowering operational costs, minimizing downtime, or mitigating the risk of unforeseen equipment issues that may impede on employees’ health and safety, ABB listens to their customers’ challenges to customize and adapt ideal solutions.

Brampton, Where Customization Thrives

Located about 30 minutes west of Toronto, ABB’s Brampton facility provides jobs for 130 employees. Firmly rooted in the local Ontarian community since 2000, the plant excels in mastering customized solutions. For customers who target cost-efficiency, the Brampton team refurbishes and repairs existing switchgears and roll-in replacement (RIR) breakers to ensure prolonged usage while adapting them to new market needs.

They also manufacture solutions from A to Z, ensuring customization to Canadian market requirements. ABB’s testing services include checking manual and electrical racking mechanisms, breaker operations at nominal, maximum and minimum control voltages, anti-pumping and trip-free capabilities, and electrical and mechanical interlocks, to name a few.

Although switchgear standard is the facility’s core business, Brampton’s unique and coveted capabilities deliver a vast array of solutions to electrification customers. These solutions include arc-resistant switchgear for Canadian customers, indoor & outdoor enclosures to withstand pressure and weather, as well as low voltage wiring and control.

The team also installs the necessary components to digitize or upgrade existing switchgear. To ensure continued reliability for such installations, they conduct proactive “health checks”, advise customers on maintenance needs and provide digital monitoring solutions.

“Our team at the Brampton facility is dedicated to providing unique customization and testing services to ensure consistent reliability and efficiency, enhance safety standards, and improve overall productivity, profitability and safety.” says Dina Morcos, Vice President Electrification Distribution Solutions, ABB Canada. “The innovative teamwork is what gives our solutions an edge.”

Customizing Energy-Efficient Solutions for Strategic Canadian Sectors

The transport of people and goods accounts for roughly one-quarter of the world’s energy consumption. When Toronto elected to expand its public transit, ABB rose to the task. The talented team at Brampton customized and adapted critical components, including AIS Switchgear for the Finch West Light Rail Transit line. They also supplied DC Breakers for the Toronto Transit Commission’s operational needs.

Canadian utilities and transportation are two of the many strategic sectors where ABB’s Brampton team showcases its customization mastery. They also helped modernize the Westshore port substation by providing medium-low voltage and delivered tailored solutions to major players in the aluminum sector, including Alcan/Rio Tinto.

Proximity is Key

Proximity is a decisive aspect when customers select a provider of customized solutions. Canadian customers prefer to work with Canadian manufacturers who are readily available to examine the delivered solutions and intervene when necessary. Proximity to the customers makes ABB a responsive, prompt, and reliable supplier with on-site, on-demand installation and maintenance services to its Canadian customers. In addition to ensuring product availability, Brampton’s added value to customers extends beyond proximity to include services provided in both of Canada’s official languages, English and French.

With its unique and skillful know-how, efficient solutions focused on sustainability in various strategic sectors, and proximity to Canadian customers in such a vast territory, ABB Brampton stands as a bright and shining example of Canadian-made expertise for Canadians.