WAGO Canada Brings Its Scalable Automation Solutions to ADM Toronto

October 15, 2025

WAGO offers Canadian manufacturers the only automation platform built on a foundation of zero-maintenance reliability.

WAGO, a world leader in automation and connectivity, will display its open, scalable automation platform at the Advanced Design & Manufacturing (ADM) Expo. (WAGO Booth #1505, Automation Hall, Toronto Congress Centre, October 21–23).

WAGO’s solutions combine multi-protocol integration, edge computing/IIoT readiness, and industry-leading reliability in I/O and controller systems. From the invention of CAGE CLAMP® push-in technology that eliminates screw terminal re-torquing to today’s portfolio of 30,000 products and global solutions, WAGO delivers a one-stop shop for automation, connectivity, and control panel solutions.

Canadian OEMs benefit from reduced complexity, faster assembly, and simplified bills of material through WAGO’s single-platform approach. End users gain increased uptime thanks to 100% vibration-proof, gas-tight, and shock-resistant connections that never require re-torquing. And with coast-to-coast Canadian sales and distribution backed by deep inventories, WAGO assures reliable product availability and supply chain continuity. WAGO’s solutions are vital for machine builders, packaging lines, and energy applications such as data centers and HVAC systems.

Automation Solutions: I/O Systems and PLC Networking

At the heart of WAGO’s ADM exhibit is the company’s I/O system, which demonstrates the “one system for every application” solution. With more than 500 I/O types — including safety, analogue, digital, encoder, and image monitoring — OEMs can configure precisely what they need without wasting space or cost. Both in-cabinet (IP20) and on-machine (IP67) solutions will be displayed. WAGO solutions support EtherNet/IP, PROFINET, Modbus, and EtherCAT communication protocols.

WAGO also showcases its PLC and networking portfolio: compact CC100 controllers, scalable PFC controllers (100/200/300), and high-powered Edge computers for advanced data processing. Managed and unmanaged Ethernet switches tie systems together, illustrating WAGO’s ability to deliver complete end-to-end automation.

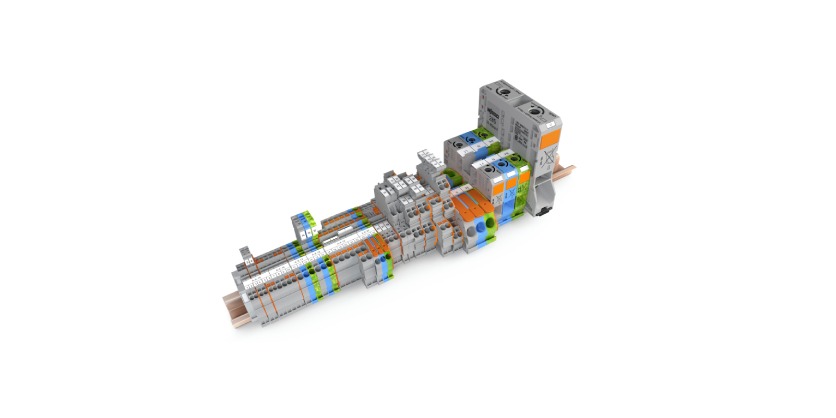

Rail-Mount Terminal Blocks: Safe, Reliable, Maintenance Free

As the inventor of spring pressure connection technology, WAGO highlights its heritage with push-in terminal blocks that are vibration proof and maintenance free. The latest lever-style designs make wiring tool free, safe to touch, and fast to install. From miniature blocks to heavy-duty 350 MCM, WAGO demonstrates why it remains the market leader in connectivity.

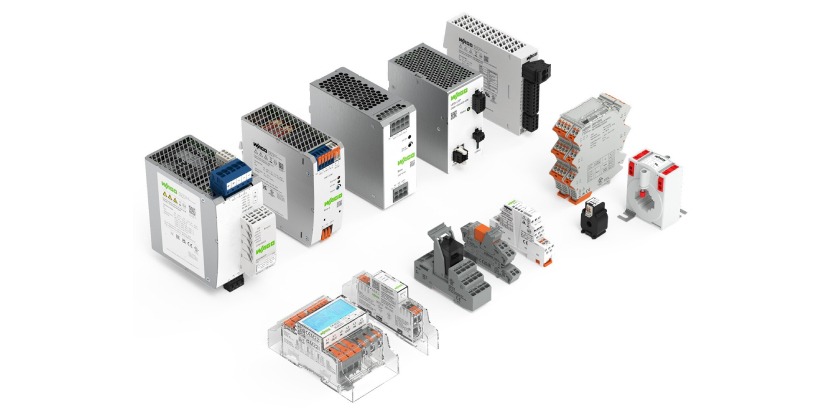

Interface Electronic Solutions: Power Supplies and Signal Conditioning

Reliable power and clean signals are essential in every control panel. WAGO’s ADM exhibit features a complete portfolio of power supplies, from 1-amp entry-level models to advanced, high-efficiency, redundant 40-amp systems. Interface modules — including electromechanical relays, solid-state relays, isolators, and signal conditioners — ensure seamless, protected communication between field devices and PLCs.

PCB Interconnect Solutions: Quick, Safe, Convenient

For OEMs of lighting, electronics, and industrial equipment, WAGO brings push-in and lever technology to the board level. The company’s PCB connector portfolio now includes higher-voltage connectors and through-panel mounting options, which emphasize speed, safety, and flexibility in assembly.

Emerging Themes: IIoT, Redundancy, and Open Software

Additional ADM highlights include:

- Convenient field wiring via lever-actuated connectors for tool-free, error-free installation.

- Application-based control redundancy ensures uninterrupted uptime in mission-critical processes.

- CODESYS 3.5 open software supports flexible, standards-based PLC programming.

- IIoT and cloud readiness with built-in protocols and function blocks that move process data securely to the cloud, enabling predictive maintenance and real-time quality control.

Corporate History

Founded in 1951 in Minden, Germany, WAGO is a family-owned company that introduced the first terminal block with spring pressure connection technology. The 1977 launch of CAGE CLAMP transformed global connection technology and remains the industry standard.

While WAGO Canada was established in 2018, WAGO products have supported Canadian manufacturers for over 30 years. Now they are backed by WAGO Canada’s dedicated sales and distribution network from Vancouver to Halifax. WAGO supports Canadian OEMs worldwide through an extensive international network, ensuring spare parts and service wherever machines are shipped.

WAGO is also a household name in the consumer market. Popular products such as the 221 Series LEVER-NUTS® and the 2773 Series WALL-NUTS® Push-in Connectors are trusted by electricians, contractors, and DIY customers, and they are widely available through electrical distributors, Home Depot, and Canadian Tire.

Visit WAGO at ADM 2025

WAGO invites attendees to Booth #1505 in the Automation Hall to explore solutions and discuss specific application needs with WAGO experts. For more information on WAGO’s 30,000 products and global solutions, visit https://www.wago.com/ca-en/.

More Information

Related Story

WAGO Expands 750 Series with New Functional Safety I/O Modules

WAGO is introducing three functional safety I/O modules to be used with WAGO’s PFC controllers. These new 750 Series modules have four safe inputs along with either two safe outputs at 10 A/24 VDC, or four safe outputs at 2 A/24 VDC each. The power outputs operate in both bipolar (high-side/low-side switching) and unipolar (common potential on one side of the load) modes. The module monitors short circuits, cross circuits, and 24 V power supply from separate sources.