Videos

-

End Effectors for Collaborative Robots

September 15, 2025

SMC’s end effectors for collaborative robots

SMC’s end effectors for collaborative robots handle workpieces of various materials and shapes, reducing setup time with plug-and-play configuration. Options include parallel air grippers, 2-finger grippers, vacuum grippers, and more, ensuring efficient and versatile material handling.

Serving Canada for over 60 years, Proax Technologies is a leading Technical Automation Distributor, offering innovative solutions in the Automation & Robotics, Mechanical Solutions, Motion Control, Machine Safety, Industrial Controls and Pneumatics industries. They support clients through preferred in-house technical solutions and are proud to represent world-class manufacturers in the industrial automation field, allowing them to offer customers the best possible products and solutions.

More Information

Connect with Proax

Related Story

Fast Delivery Meets Versatility: The All-New SMC AC-D Series

Modern design, unmatched adaptability, and effortless assembly – engineered for your business’s efficiency. Explore how the SMC AC-D Series delivers unmatched versatility, efficiency, and reliability. Designed with modern features and user-friendly assembly, this series is built to simplify your operations while maximizing performance.

-

HPS Power Quality Products

August 28, 2025

HPS Power Quality Products

HPS offers a full line of products to address power quality issues in your facility. Good power quality is important to maintain critical operations, improve energy efficiency and prevent premature equipment failure. Examples of poor power quality include harmonic distortion, reflected wave voltage, and low power factor.

HPS Power Quality products include active harmonic filters, passive harmonic filters, dV/dT filters, sinewave filters, line and load reactors, drive isolation transformers, harmonic mitigating transformers and multi-pulse transformers.

More Information

Related Story

Hammond Power Solutions Quarter 2 2025 Financial Results

Hammond Power Solutions Inc. (“HPS”), a leading manufacturer of dry-type transformers, power quality products and related magnetics, has recently announced its financial results for the second quarter 2025.

They are pleased to share that HPS delivered another strong quarter in Q2 2025, achieving record sales and solid profits despite navigating some cost headwinds. Their quarterly revenue reached approximately $224 million, marking a new record quarter with 14% growth compared to Q2 2024. Their gross margin was slightly lower than the previous year due to rising input costs and further investments in their manufacturing footprint.”, said Adrian Thomas, CEO of Hammond Power Solutions.

-

Meet Omron, a Company That Combines Society, Science and Technology

August 28, 2025

As a global leader in the field of automation, Omron’s business fields cover a broad spectrum, ranging from industrial automation and electronic components to social systems including automated ticket gates and solar power conditioners, healthcare. At present, the company provides products and services in more than 130 countries.

They use their extensive portfolio to build integrated solutions that optimize manufacturing and improve safety. With proof-of-concept centres located throughout the world, they give customers the freedom to create world-class products using solutions they can trust.

More Information

Related Story

How Can Omron’s Certified System Integrator Partners Elevate Your Automation Solutions?

With so many companies offering system integrator services in the automation industry, finding the right partner can be a daunting task. They understand the importance of seamless integration, efficient automation, and adaptable manufacturing process. That is why they introduced their Certified Systems Integrator Program – a platform designed to elevate their partners’ proficiency in Omron technology. Their goal is to empower their partners to enhance productivity and cost-effectiveness for mutual customers.

-

Reliable Wireless Edge Computing With MOXA Quad-Core Arm-Based Computers | ManuAuto

August 25, 2025

Say hello to the Future of Industrial Computing — the New MOXA UC-3400A & UC-4400A Series are here! Built for today’s connected operations, these next-gen Arm-based computers pack the performance, security, and wireless features you need to stay ahead.

Whether you’re monitoring machine health on the factory floor or optimizing semiconductor production with 5G-ready tech — these devices are built to deliver.

More Information

Ready to upgrade your OT systems the smart way? Discover how these compact powerhouses can drive real results in your operations.

Related Story

MOXA Next-Generation LAN Firewalls: Enhancing Industrial Security and Reliability

Cyberattacks on critical infrastructure have become an all-too-familiar reality. While no longer shocking headline news, their effects are far-reaching, disrupting essential services that people and organizations rely on daily. From power grids to transportation systems and water treatment facilities, these infrastructures are at the heart of modern life and are highly vulnerable to cyber threats.

-

Weidmüller PROeco II Power Supplies

August 25, 2025

Introducing the new PROeco II power supply series — the next generation of compact, efficient, and cost-effective power solutions from Weidmüller. With up to 95% efficiency, a 15% smaller footprint, three-color status signalling, and improved MTBF, PROeco II is built to meet the demands of modern industrial automation while fitting seamlessly into existing designs.

More Information

Related Story

Weidmuller Ltd. Canada Opens New Calgary Office to Strengthen Presence in Western Canada

Weidmuller Ltd. Canada is pleased to announce the opening of its new office in Calgary, Alberta—marking a significant milestone in the company’s ongoing national expansion. Strategically located in Southeast Calgary, the new facility will serve as Weidmuller’s regional hub for Western Canada, supporting operations across British Columbia, Alberta, Saskatchewan, Manitoba, Yukon, Northwest Territories, and Nunavut.

-

HPS EV Charging Distribution Transformers – Built to Brave the Elements

August 12, 2025

HPS EV Charging Distribution Transformers – Built to Brave the Elements

As electric vehicle (EV) infrastructure expands, transformers play a critical role in powering EV charging stations with reliable, efficient energy. HPS EV charging transformers are designed to manage the high and fluctuating loads of EV charging, delivering consistent performance in demanding conditions.

With advanced dry-type transformer technology and an optional robust 3RE+ enclosure that provides superior protection over standard ventilated designs, HPS EV charging transformers offer durability, energy efficiency, and dependable operation for high-volume and fast-charging applications.

More Information

Electric Vehicle (EV) Charging Distribution Transformers

Related Story

Designing for Demand: The Role of Transformers in a Resilient EV Future

As electric vehicles (EVs) continue their rapid rise, one question looms over the energy sector, municipalities, and developers alike: Is our infrastructure truly ready for the surge in demand?

From city streets to highway rest stops, new EV chargers are popping up across North America. But while charging stations get all the attention, there’s a critical component working behind the scenes, often overlooked, but absolutely essential: the transformer.

-

Safety Gate Protection with PSENmgate | Pilz

July 28, 2025

Do you have several protective devices on your machines and systems such as doors, flaps or hoods? And do you need protection that enables you to work safely and ensure a reliable production flow? In this video, you will learn all about the functions and benefits of the PSENmgate safety gate system. The PSENmgate combines safe guard locking with the appropriate operating unit and offers you a comprehensive solution for protecting your machines and systems.

Safety gate system PSENmgate

The PSENmgate is characterised by its robust construction, which is designed for use in demanding environments. It ensures maximum reliability and efficiency in your production by providing safe and stable guard locking. The simple installation and user-friendly design enable quick and uncomplicated assembly. The safe guard door system is flexible in use and can be easily adapted to different applications and requirements, making it ideal for a wide range of industrial applications. Whether in the automotive industry, packaging plants or other sectors – the PSENmgate offers you safety and flexibility.

About Pilz

Pilz is shaping the future of industrial automation

Pilz is a global supplier of automation products, systems and services. They never compromise when it comes to safety for human, machine and the environment. As a family business steeped in tradition, with a worldwide presence, their aim is to be a reliable partner for you locally. In everything they do, they want to make the world a safer place. This is apparent in every idea, every product and every solution that’s developed at Pilz. They always focus on their customers’ needs and are passionate about supplying them with cutting-edge technology and the very best quality.

More Information

Safety gate system PSENsgate / PSENmgate

Related Story

Safety Locking Device PSENmlock from Pilz

The safety locking device PSENmlock offers safe interlocking and safe guard locking for personnel and process protection, up to the highest category PL e.

Safe guard locking is enabled by the dual-channel control on the guard locking device. As such, the switch is particularly suitable for use on machines with a hazardous overrun, which require safe guard locking up to PL d or PL e.

In conjunction with Pilz control technology, the result is a safe, complete solution for monitoring and activating guard locking on guards.

-

How ABB Canada Supports Grid Resilience in Extreme Weather Events

July 23, 2025

How ABB Canada Supports Grid Resilience in Extreme Weather Events

Extreme weather events are no longer rare in Canada. From ice storms to wildfires, the impact from harsh weather on our electrical grid is growing. And as cities expand and energy demands rise, utilities are under more pressure than ever to keep the lights on and businesses operating.

At ABB Canada, they are here to help.

✔️ Their national distribution centre in Bromont, Quebec is stocked and ready to ship critical components at a moment’s notice.

✔️ Their teams across the country provide local, on-the-ground support.

✔️ Their technologies help build a more resilient, affordable and sustainable grid.

With over 60 years of experience supporting Canadian utilities, ABB Canada remains a trusted partner—ready when and where it counts.

More Information

Learn more about ABB’s utility solutions: https://campaign-el.abb.com/utilities-en

Related Story

ABB Designs Time-Saving ENT Fittings for Construction Projects

As Canada’s construction industry prepares for long-term growth, durable, locally produced materials and efficient installation methods are propelling the industry forward. An essential component of building electrical systems, ABB Installation Products engineered new Carlon® Flex-Plus® Blue electrical non-metallic tubing (ENT) two-piece fittings to help speed and simplify conduit installations and meet demanding project timelines.

-

Meet ABB’s LV Titanium Variable Speed Motor: The Future of Industrial Powertrain Performance

July 22, 2025

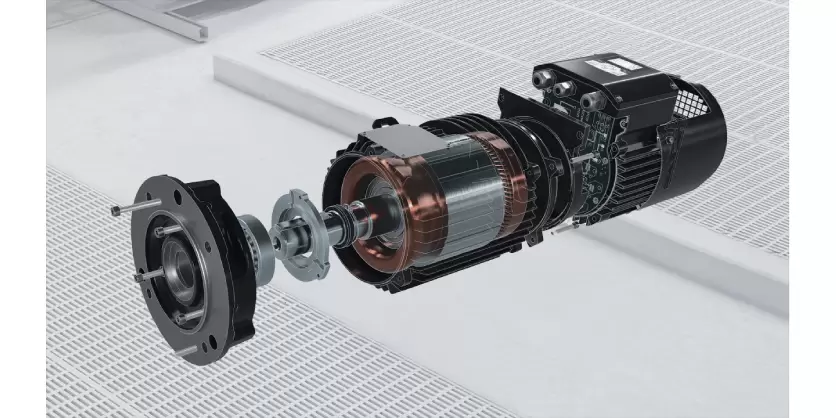

Meet ABB’s LV Titanium Variable Speed Motor

Demand more from every component. Introducing ABB’s LV Titanium variable speed motor: an integrated powertrain built for maximum performance, ultra efficiency, and simplified installation.

Engineered to outrun the competition, this plug-and-play solution is designed for one-person setup and thrives in the toughest industrial environments. With IE5 ultra-premium efficiency, low noise operation, and the ability to cut energy consumption by up to 30%, the LV Titanium helps you boost performance and ROI — whether you’re pumping, compressing, or ventilating.

With decades of ABB expertise behind it, LV Titanium is ready to move your operation forward — faster, smarter, and more efficiently.

ABB: Engineered to outrun.

More Information

Related Story

ABB Unifies Motor and Drive in a Streamlined Plug-and-Play Platform

ABB’s new LV Titanium Variable Speed Motor platform delivers the benefits of a high-efficiency motor and variable speed drive (VSD) technology in a single, compact, customizable, plug-and-play solution that enables industrial customers to minimize their energy consumption, save money and reduce carbon emissions.

The LV Titanium offers a simple and cost-effective way to provide IE5 Ultra-Premium efficiency for pumps, compressors and many other applications. As a drop-in replacement for existing direct-online (DOL) induction motors, the Variable Speed Motor provides an easy upgrade path to a VSD-driven motor with a fast ROI.

The innovative LV Titanium platform is far more than a drive simply bolted on to a motor. Instead, it is engineered as a fully integrated concept, with an advanced drive module purpose-designed from the outset for optimal performance with a high efficiency permanent magnet (PM) motor. This sleek, streamlined design, with the axial drive mounted on the end of the motor, saves space and makes the LV Titanium ideal for applications like vertical pumps. It is also remarkably quiet in operation.

A further advantage is that it can operate over a wide range of speed and torque requirements, with the capability to deliver high torque at low speeds.