Vario-X Decentralized Automation – Zero Cabinet

February 14, 2023

Vario-X, The key towards digital transformation

In the world of automation, no stone is left unturned. Literally everything is put on the test bench. And the purpose is clear: digital planning, easier and faster installation and commissioning, cost efficiency and sustainability.

Murrelektronik enables you to meet these increasingly complex goals – with inventive solutions. Decentralized automation in a modular system makes your plant ready for the future and gives you space when production floors reach their capacity limits.

Simple and intelligent. Customized.

Future-proof all along the line.

Decentralized automation system – zero cabinet

Into the field, decentralize, modularize, combine technologies, act more energy efficiently, reduce and simplify complexity and find smart solutions.

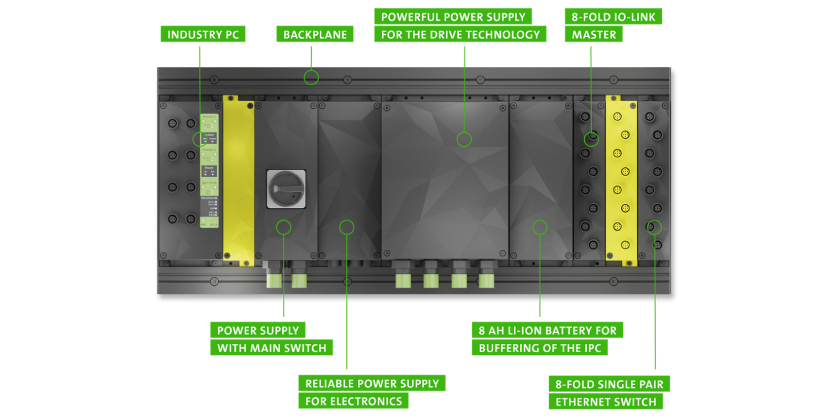

This is what Vario-X achieves: 100 percent decentralized automation without control cabinets. The Vario-X system solves increasingly complex production challenges. Vario-X is a modular system with solutions for every machine need imagined down to the smallest detail. You can plan and expand your system according to all the rules of the art – flexible, scalable, machine mountable and compact.

Our decentralized system eliminates the need for time-consuming installation. Set-up times and error sources are eliminated. Service and down-times are adjusted to your production cycles through predictive maintenance. Sounds complex, but Murrelektronik makes it quite simple!

The future of automation is cabinetless.

Vario-X is a consistently flexible and scalable automation platform with maximum openness and performance on all levels and at all interfaces. Because the future of automation is without control cabinets and without compressed air – but networked, pluggable and cost-efficient.

Olaf Prein, Head of Global Business Unit Automation at Murrelektronik

Smart and simple

Vario-X is a modular automation platform that provides a customized solution. It is developed and engineered according to the customer’s individual requirements and brings all automation components directly to the point of action. The system consists of:

With seamless integration of decentralized servo drives, it ensures reliable voltage, signal and data management directly in the field. This means that, for the first time, all automation functions can be implemented completely decentrally – without a control cabinet. The robust housings with IP67 protection (waterproof/dustproof) are simply snapped side by side into a solid backplane with integrated machine construction profiles. In this way, the entire station can be easily attached to all common profile systems without any further protection and, in extreme cases, can even withstand a stepping load on the housings.

Positive side effects in terms of energy efficiency and space requirements: When control cabinets become superfluous, less cooling is needed and more space is available on the shop floor that can be used for value-added manufacturing equipment such as robots.

Digital Twin for Planning, Installation, Operation and Service

However, VARIO-X is not only backplane, controls, cables & Co. The plant automated by VARIO-X has a digital twin right from the start. A movable 1:1 image of the real plant, which contains all functions and parameters of the later system – and this already in the project phase before even the first mechanical component has been ordered or assembled.

More Information

Related Product

Murrelektronik: Xelity IP20 Managed Gigabit Switches – Intelligent Networking

Switches perform central tasks in networks. As intelligent infrastructure components, they read incoming data and forward it to the port with the corresponding receiver.

Murrelektronik’s Xelity IP20 Managed Switches allow Ethernet devices communicate with each other via network connections. They give the network the option of setting up different topologies, like star or tree. In addition, the switches can perform other tasks including error analysis or network diagnostics. They optimize data transmission and provide network control through remote access.