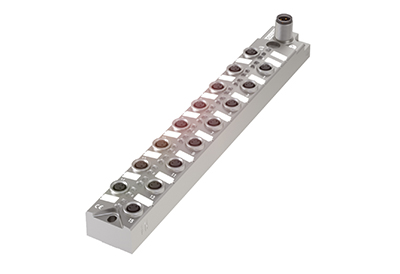

I/O Hubs With M8 Connectivity Simplify Integration, Reduce Costs

January 11, 2019

Balluff’s newest I/O hubs deliver M8 quick connect to enable resilient distributed modular architecture for compact footprint machines and end effectors.

Balluff’s new M8 I/O hub portfolio enables Balluff IO-Link masters to host up to 248 discrete sensors on a single network node. This replaces the need for up to 16 network blocks and eliminates the associated costs for integration. Use of M8 sensors and actuators are primarily geared toward compact footprint machine designs or light weight designs.

Typically, M12 network blocks are used with splitters to integrate M8 sensors in case of distributed architectures. This requires multiple network blocks and splitters which create numerous failure points and add to the overall project budget. Balluff’s M8 I/O hubs eliminate the additional cost of adding network nodes and splitters by simplifying integration with direct M8 connectivity and unique expansion port strategy.

Ports on the configurable hub can be freely configured as input or output, providing short circuit and overload protection per port. Like its M12 I/O hub portfolio, the Balluff M8 portfolio has IP67 robust metal housing suitable for most harsh industrial environments, has input only and has a configurable I/O option.

The key features of M8 portfolio includes:

- Compact metal IP67-protection-rated housing

- 8-channel and 16-channel design for perfect application fit

- Ports on configurable hub can be freely configured as input or output, providing short circuit and overload protection per port

- Enhanced diagnostics with IO-Link

- 300mA output per channel and max 1.6A per I/O hub