Flexible Workpiece Handling for Robots from SCHUNK

August 21, 2025

SCHUNK is expanding its end-of-arm solutions to ensure future readiness and is introducing the robot PLUS product portfolio. One of the highlights is the new CPS tool changer, which enables the automated exchange of end effectors on the robot. The technology pioneer thus offers potential for versatile robot applications with short changeover cycles.

Flexibility is essential in automated manufacturing. The growing variety of process steps requires agile interaction between the tools and systems involved. With a change system, robots can perform various handling or machining tasks flexibly and without additional set-up effort. Downtimes can be reduced to a minimum. The new SCHUNK CPS tool changer is a flexible all-rounder for the automated exchange of end effectors on the robot.

Flexibility made in Germany

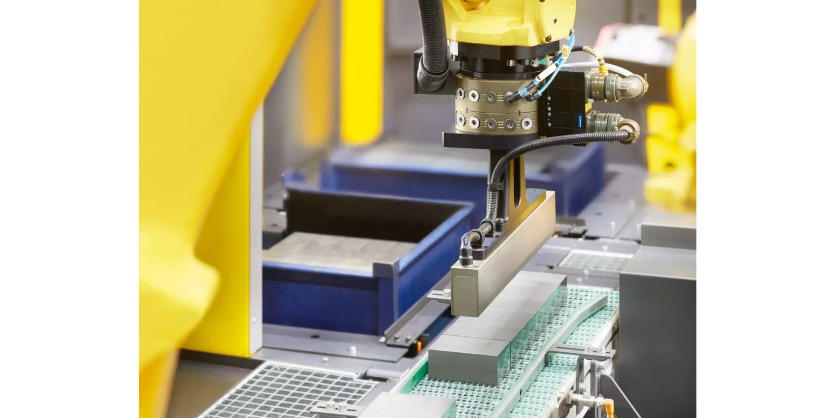

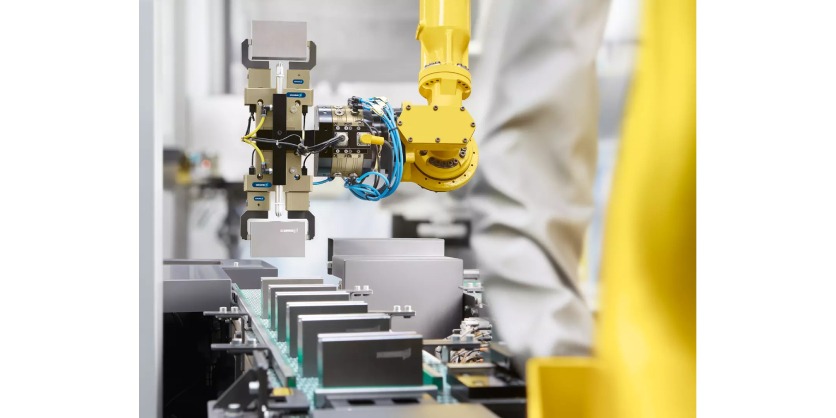

The raw parts are magnetically removed from the tray and then loaded and unloaded in a single step using a pneumatic dual gripper unit. With the help of a change system, a robot can perform this process fully automatically. For the new CPS tool changer, SCHUNK deliberately focused on versatility. The pneumatically controlled system enables the fast and reliable exchange of grippers and other tools with handling weights of up to 1,000 kg at the frontend. The CPS series includes 18 sizes, ensuring that users can find the right changer for any robot.

Focus on safety and efficiency

The CPS consists of a change master (CPS-K) and a change adapter (CPS-A), which interlock positively and reliably via compressed air. An integrated spring minimizes gap formation in the event of an unexpected drop in air pressure and ensures self-retaining locking at the same time. Optional sensors increase transparency in process monitoring by detecting both the locking status and tool presence.

A wide range of signal, pneumatic, fluid, and communication modules further expands the functionality and application possibilities of the CPS.

The tool changer can be used with a robot or even stationary, e.g. in the fixture construction. Because it is fully compatible with existing SCHUNK changers, users do not have to teach them again when exchanging. Mounting of the change master onto the robot is very easily done via ISO flanges or standardized adapter plates. The use of hardened steel in all functional parts makes the CPS particularly robust and durable, even in harsh machine environments.

Robot PLUS

With the new Robot PLUS portfolio, SCHUNK offers versatile design possibilities for flexible robot automation. In addition to tool changers such as the CPS and CPB, the comprehensive portfolio also includes newly developed compensation units and force/torque sensors. Thanks to its decades of expertise in developing precisely engineered, well-conceived automation modules, SCHUNK stands for particularly high productivity, flexibility, and resource efficiency.

Related Story

SCHUNK – Electromechanical Workpiece Clamping Technology

Digital technologies create more energy-saving, efficient and flexible manufacturing processes. They are key components for a “Healthy Factory,” a production facility that is both healthy and economically successful. With this goal in mind, SCHUNK is also making its clamping devices increasingly parameterizable and networkable. The advantages are particularly evident in the machining of small and medium batch sizes and in transparent process monitoring. For this purpose, SCHUNK has added an electrically driven version with a freely programmable clamping stroke to its proven KSX series of 5-axis vises – the KONTEC KSX-E.