Orion Fans launches specialty fan filters offering low pressure drop, water resistance and fire protection

February 19, 2019

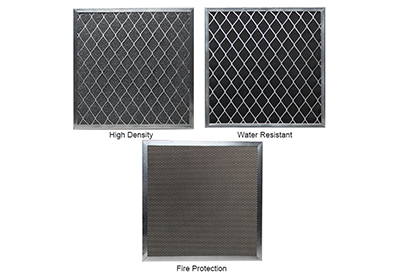

Orion Fans has designed a series of specialty air filters for equipment where permanent, cleanable filters are most appropriate. When combined with an Orion Fans louvered filter fan kit or louvered fan guard (LFG Series) snap-on, slide or hinged versions, Orion Fans’ specialty air filters provide low pressure drop, water resistance or fire protection. With the ability to capture large amounts of airborne dust in industrial enclosure applications, the FHD Series (high density), the FHDH Series (water resistant) and FHDP Series (fire protection) are essential filtration solutions for networking and communications equipment where compliance to NEBS, ATCA and other industrial computer specifications are required. These filters also meet MERV rating for HVAC and air handling applications.

The FHD (high density) Series is a foam air filter that delivers low pressure drop, fire resistance, and the ability to capture large amounts of airborne dust in industrial enclosure applications. High density foam air filters are available in a broad range of porosities (PPI) to meet custom filtration performance requirements. The standard is 45 PPI. The filters comply with UL 94 HF-1 self-extinguishing flame safety standards for electronics in industrial, medical, telecom, power gen and military electronics air filter applications.

The FHDH (water resistant) Series is a hydrophobic mesh air filter that features a water-repellent, low pressure drop media to reduce ingress of airborne mist and other liquids in harsh environment enclosures. The FHDH Series is a cost-effective alternative to expensive, more air flow restrictive membrane media. The hydrophobic filter media is a durable, cleanable, moisture-resistant solution for indoor/outdoor cabinets and process equipment requiring mist elimination zones. The hydrophobic mesh will help meet various enclosure-level standards such as MIL-STD, NEMA and IP ratings.

The FHDP (fire protection) Series are PyroCide air filters that can be used for electronics enclosure applications that require stringent flame safety standards. The filters are aluminum honeycomb thermal barriers treated with a heat responsive intumescent flame coating for fire containment in electronics enclosures. The filters are designed with thin profiles and configured with aluminum honeycomb that provides low resistance to airflow. Edge-to-edge venting requirements and intricate designs are combined with precision metal fabricated aluminum frames and housings.

“To better meet our customers’ needs, we launched our Specialty Filters Series that provides cost effective and high-performance alternatives. These new filters for filter fan kits and louvered fan guards meet vital industry standards for ruggedness and reliability,’’ said David Luna, VP of Marketing at Orion Fans.

For more information about Orion Fans’ Specialty Filters, go to https://orionfans.com/group.php?k=20.