Omron to Unveil New Systems at IPC Apex Expo 2023 to Extend the Automated Inline Inspection to Every Step of the Manufacturing Process

December 19, 2022

High-speed, high-quality, and cost-effective automated inspection is essential for electronics manufacturers. With two new inspection systems, Omron continues to enable more companies to choose the best technology for monitoring production fan quality in real-time.

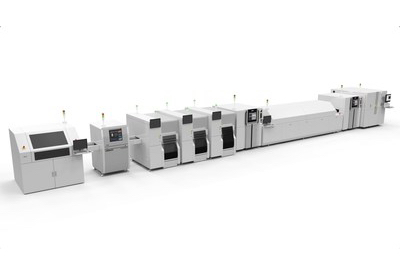

Omron Automation Americas, a global leader in automated optical inspection (AOI), automated x-ray inspection (AXI) and solder paste inspection (SPI), will introduce two new AOI systems at IPC Apex 2023 in San Diego: the VT-Z600 and VT-S1040. Its inspection systems use advanced hardware and sophisticated image processing to deliver exceptional reliability and performance at production speeds.

The VT-Z600 is Omron’s fastest pre/post reflow AOI system. It features multi-direction and multi-color (MDMC) illumination to achieve a new level of stable and flexible inspection.

The VT-S1040 is also intended for pre/post reflow inspection. It too features MDMC illumination but also includes AI-assisted, micro phase shift (MPS) 3D reconstruction, which further improves defect detection and first pass yields while reducing false calls.

Both systems incorporate robust Omron hardware, are designed to have a long operational life in the most demanding manufacturing environments and can be field upgradable in the future.

“IPC Apex Expo is a great venue for answering technical and process questions and showing new systems like the VT-Z600 and VT-S1040,” says Brad Ward, technical manager for advanced sensing and inspection solutions at Omron. “It’s a low pressure environment that allows customers to fulfill a key stage of their crucial technology evaluation.”

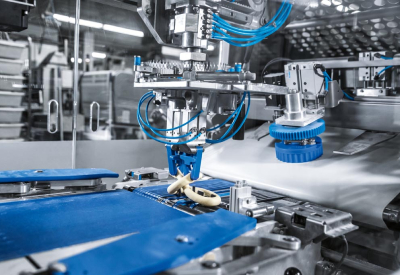

Omron will also showcase its impressive VT-X750 inline CT X-ray inspection system. The VT-X750 CT AXI is a true 3D system and a popular choice for critical SMT, THT and press-fit device inspection across all industries including: 5G, automotive, aerospace and medical products. It’s unique imaging technology easily identifies the widest array of BGA solder joint quality and reliability issues, including voids and difficult to image hidden-in-pillow (HiP) defects.

Experts will also answer questions about the Omron Q-upNavi software suite that allows machine-to-machine (M2M) communications between SPI, AOI and AXI systems. Q-upNavi improves quality control and manufacturing output by integrating data from every inspection point. It provides companies with tools to easily analyze, visualize, and monitor the manufacturing environment. Omron customers use the technology to create Smarter Factory environments that support their Industry 4.0 goals such as moving beyond simply catching defects to achieve true process improvement and zero defect manufacturing lines.

To learn more about the inspection technology, visit Omron Inspection Systems by clicking here