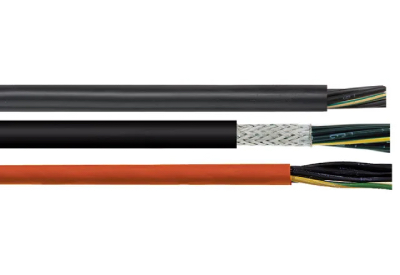

ÖLFLEX® HEAT 260 SC from LAPP

August 22, 2022

For use in the most extreme conditions

ÖLFLEX® HEAT 260 SC – PTFE single core, robust, chemical resistant and space-saving, for use in machine and plant construction at temperatures: -190°C to +260°C

- •Excellent chemical, thermal and electrical performance

- •Space and weight-saving

- •UL AWM Style 11486 (28-12 AWG)*

Product Features

- •Flame retardance rating (UL): FT2 (Horizontal flame test)

- •Flame-retardant according to IEC 60332-1-2 & CSA FT1

- •Made of PTFE

- •Outstanding resistance against acids, alkalis, solvents, lacquers, petrol, oils and many other chemical media

- •Difficult to inflame

- •High dielectric strength and high abrasion

resistance - •Low water absorption

- •Resistant to microbes

- •Adhesion-free insulation materials

- •Weather and ozone resistant

- •Hydrophobic and dirt-repellent

- •High elongation and tear resistance

- •Resists contact with liquid nitrogen

- •Resistant against hydraulic fluids

- •Silver plated copper is characterized by good surface conductivity (skin effect) and good solderability

Why ÖLFLEX® HEAT 260 CS?

- •Small outer diameters for maximum saving of space and weight

- •Resistant to contact with mostly all highly aggressive chemical media

- •Stress crack resistant to frequent ambient temperature fluctuations

- •For use in environments with very high operating temperatures, heavy usage of chemical agents or confined spaces

If you have any questions or are interested in connecting with one of their experts, please connect with them by clicking here