Siemens Innovates SINAMICS S210 Servo Drive System with New Hardware and Software for An Even Larger Range of Applications

January 22, 2024

- New V6 software generation with new functions like a single positioner to reduce the load of the controller, and EtherNet/IP to allow third-party controllers to be connected

- Simulation via DriveSim Advanced enables virtual commissioning in advance, ensuring drive process requirements are met efficiently and cost-effectively

- New hardware architecture with functional enhancements like a second encoder interface and 3C3 (H2S and SO2) coating increases precision and robustness

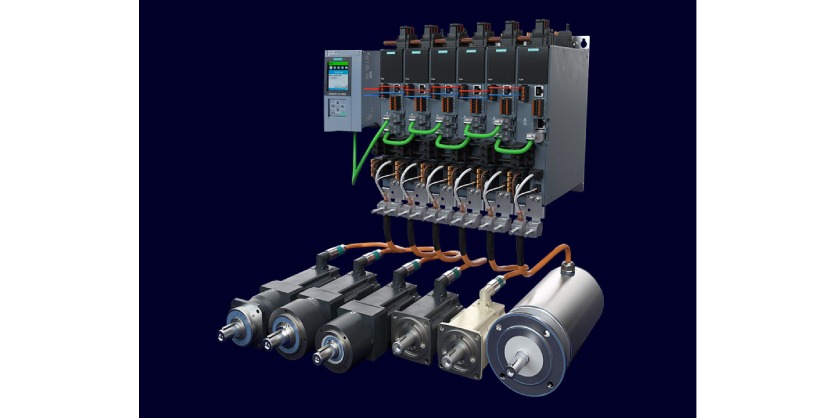

Siemens is innovating the well-established Sinamics S210 servo drive system with a new hardware architecture and new V6 software generation that expand the system’s range of applications. The servo drive system is especially suitable for applications with high dynamics in the power range between 50 W and 7 kW: for example, machines for packaging, pick & place applications, and digital printing.

To make it even easier to control individual axes in the future, the new generation of the Sinamics S210 comes with a second encoder interface and offers the option to connect a direct measuring system to compensate for mechanical looseness and tolerances. This significantly increases precision, which makes more applications possible.

With its Basic and Extended Safety Integrated functions, the new Sinamics S210 ensures the comprehensive implementation of the safety concept in the machine and meets the requirements of SIL3 (EN 61508) and PL e (EN ISO 13849-1). Another new feature of the system is the Security Integrated functions that ensure greater safety in industrial systems with user management and access protection.

Also new: In addition to Profinet IRT, the Sinamics S210 now offers communication via EtherNet/IP. This means that third-party controllers can also be connected to the servo system, which significantly increases the range of applications, especially in the U.S. market.

With the new 3C3 (H2S and SO2) coating, the new generation of the Sinamics S210 is extremely robust and can resist aggressive environmental influences like sulfur gases. This means that the servo system also guarantees high system availability and productivity under difficult production conditions: for example, in the tire industry.

The EPOS single positioner is now also available as a technology function for the Sinamics S210. With this function module, high-precision motion control positioning tasks can be implemented quickly and easily in the converter because positioning tasks can be calculated directly in the drive. This reduces computing power in the controller, which can instead calculate more complex tasks or a larger number of drive axes.

The new generation of the Sinamics S210 also enables the simulation of motion control applications. Using the DriveSim Advanced simulation software, a digital twin of the Sinamics S210 can now also be created in the TIA Portal. This can be used to virtually commission the drive system in advance and perform engineering tasks. Requirements for the processes in the drive train can therefore be ensured cost-effectively and efficiently.

In addition, the digital twin offers the opportunity to create virtual training courses and demonstrations and to optimize real machines by eliminating problems in the drive train, which are simulated with the digital twin.

A well-established feature of the Sinamics S210 is the integrated Web server, which has been redesigned to support the new Web server platform and operating philosophy of the new Sinamics inverter generation: for example, the Sinamics S200 and Sinamics G220. The Web server enables efficient commissioning, fast diagnostics, and maintenance from a variety of devices like tablets and PCs.

More Information

The new servo drive SINAMICS S210 – More features, more possibilities

Related Product

The New SINAMICS S200 Servo Drive System from Siemens: Move Beyond!

Siemens recently released their new SINAMICS S200 servo drive system. It is designed to address a wide range of standard applications, including battery, packaging, handling and robotics, metal forming, and other general machinery. The S200 has been optimized for performance, is easy to use, and is fit for the future. Bimal Shah P.Eng., Head of Product Management and Applications Engineering at Siemens Canada discusses their new servo drive system.