Nidec Sells 100,000 E-Axles Globally

February 3, 2021

Nidec Corporation has recently announced that the global sales of E-Axles, the traction motor systems that the Company develops, produces, and sells, have reached 100,000 units and systems.

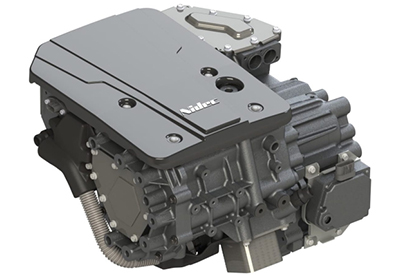

Nidec’s E-Axles are characterized by being compact and light-weight as a result of their fully integrated designs that combine motors, inverters and gears. In addition to the Ni150Ex 150 kW model that became the first fully integrated traction motor system of its kind in the world designed by a supplier to enter mass-production in April 2019, Nidec has also developed four other models: Ni200Ex (200 kW), Ni100Ex (100 kW), Ni70Ex (70 kW) and Ni50Ex (50 kW). Armed with this world-class comprehensive lineup, Nidec is capable of supplying traction motor systems that can power an estimated 98% of all electric passenger vehicles. Nidec has set a target of achieving 40 – 45% global market share in the EV traction motor market by 2030, and the E-Axles will serve as an engine of this effort.

As Europe, China and many other countries in the world announce a ban on selling new gasoline vehicles to take effect in 2025 – 2040, Nidec stays committed to developing products based on its technology to make light, thin, short and compact products and improve products’ efficiency and control performance. With these technologies that it has been fostering as the world’s leading comprehensive motor manufacturer, Nidec is poised to provide, at a massive pace, revolutionary solutions that contribute to the evolution of automobiles and CO2 reduction.

Cars driven by Nidec’s E-Axles (as of January 1, 2021) (in order of launch date)

- 1. GAC Aion New Energy Automobile, Aion S

- 2. GAC Toyota Motor, iA5

- 3. GAC Aion New Energy Automobile, Aion LX

- 4. GAC NIO New Energy Automobile Technology, HYCAN 007

- 5. Geely Automobile, Geometry C

- 6. GAC Aion New Energy Automobile, Aion V