Nidec Develops Proof of Concept (PoC) for Digital Twin-Type Intelligent Motor®

August 8, 2023

Nidec Corporation has announced that it has developed a proof of concept (PoC) to realize an “Intelligent Motor® solution,” a system that the Company defined to adapt (i) Intelligent Motors®*1 , which are equipped with microcomputers and data coupling and time synchronization functions, and (ii) products with an Intelligent Motor®, to digital twin*2 .

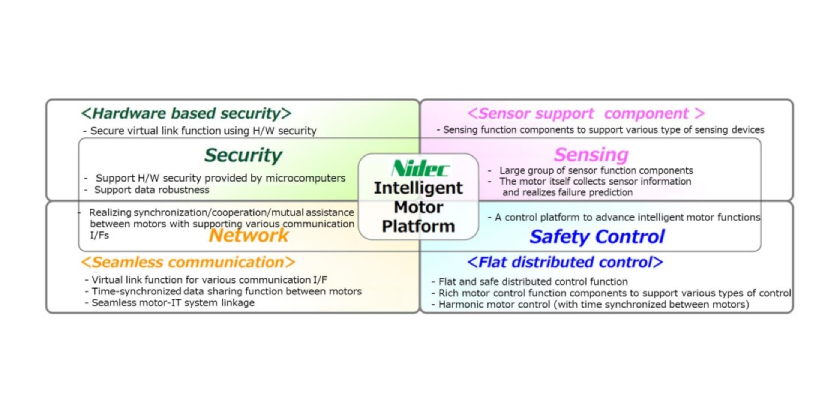

As DX and ICT (Information and Communication Technology) become a mainstream of the time to serve as solutions for labor shortage-stricken production sites(that are struggling with factory launch, education, supervising, maintenance work, etc.), Nidec has successfully created the following three solutions that comprise the technical features of Intelligent Motor® solutions for such issues:

- A system to reproduce issues from reality in a virtual space and conduct a test (cloud technology);

- A system where even those not experts in 1 above can reproduce such issues in a virtual space (GUI technology); and

- A system to incorporate edge computing into a motor, and bring it to the IoT market.

In verifying the aforementioned concept, Nidec selected a triaxial parallel link robot*3 as our theme this time, after anticipating proposing Intelligent Motor® solutions to robot manufacturers. With intelligence-equipped motors operating in collaboration with one another and with high accuracy, the Company succeeded in operating a robot without the use of a central control unit, while reproducing the robot’s virtual counterpart in a virtual space.

Thus, using GUI fully, Nidec designed and verified the virtual robot’s operation program, and developed a next-generation development environment that reflects the operating program in the robot in the actual space via wireless communications, to verify the above functional operations (For more details on the background of this development and technical features, please see the “Reference” section on Page 2 and after of this press release).

The above technology can: (i) reduce, or even eliminate, the load on motor-assembled equipment’s central control unit; and (ii) verify any changes to the system – ranging from changes to a motor’s application to issues that occurred in the workplace – in a cloud-based virtual space, and implement those changes in the actual space in real time. Hence, the technology will likely serve as a solution for labor shortage at factories around the world by creating a digital twin world easily.

Nidec is poised to provide this Intelligent Motor® solution to enhance the additional values of motors in the world, and create a more affluent society.

Related Product

Nidec Develops New Column-Type EPS-PP Electric Power Steering Motor Power Pack

Nidec Corporation has announced that it has successfully developed a new electric power steering motor power pack*1 EPS-PP.