New Rockwell Automation Studio 5000 Logix Designer Software Release Enhances Productivity, Saves Time

October 19, 2020

Controls engineers can design machines and process applications faster using the latest release of the Studio 5000 Logix Designer software. Rockwell Automation has updated the software with productivity enhancements and new capabilities that can speed up projects for process applications specifically.

Productivity enhancements in version 33 of the Studio 5000 Logix Designer software include:

- – Auto-generated diagnostics for supported devices that reduce programming time and give users access to detailed, contextualized diagnostic information.

- – Preservation of online controller tag values when making offline changes and conducting sequential downloads, eliminating the need to re-establish tag values.

- – Extended tag properties that allow engineers to leverage contextual data to create more descriptive and powerful HMI elements, while reducing programming time.

When paired with the new Allen-Bradley ControlLogix and CompactLogix process controllers from Rockwell Automation, the latest version of Studio 5000 Logix Designer can also accelerate process projects in key ways:

- – Embedded process instructions can save engineers time and reduce compliance work.

- – HART integration allows engineers to connect HART devices just like they do EtherNet/IP devices, enabling smoother integration with fewer software tools.

- – Prebuilt task models reduce the amount of time spent on project creation and layout and can improve consistency across projects.

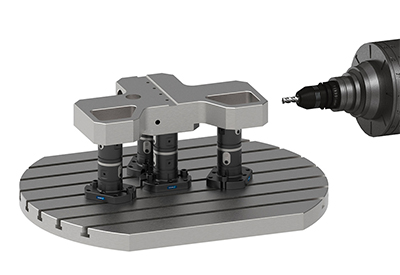

Additionally, version 33 of Studio 5000 Logix Designer can now be used in projects that require an Allen-Bradley ControlLogix 5580 redundant capability. The software also can be used with the new iTRAK 5730 small-frame system for projects like primary packaging in food and beverage.