Mitsubishi Electric: iQ-F Simple Motion with Low Cost Servo

November 15, 2018

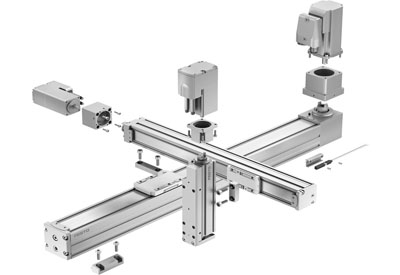

State of the art motion performance is packed in this Simple Motion Module for the iQ-F series micro PLCs. Combine the FX5-40SSC-S or FX5-80SSC-S Simple Motion Module with the SSCNET III/H compatible MR-JE-BF with STO servo system to knock out the competition at cost-sensitive OEMs with top-of-the-line features without the top-of-the-line price.

This combination brings high performance network based motion control to the low cost market. Powerful features borrowed from the flagship products add unprecedented value to this simple motion control solution.

- Flexible – Wide range of features available to improve ease of use and system performance.

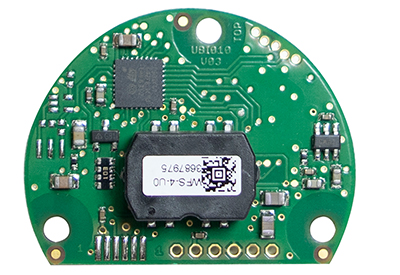

- MR-JE-BF servos with safety – Combine advanced features such as the SSCNET III/H motion network interface and one-touch tuning in a low cost system in sizes from 100W to 3kW.

- Synchronized motion control – 4 or 8 axis of synchronized motion are available enabling functions like camming, gearing, registration and A800 VFD connectivity.

- SSCNET III/H communication – This high speed, deterministic, synchronized communication network features high speed noise immune communication, and simplicity that simplifies troubleshooting, and maintenance.

- Encoder following – Built-in encoder interface simplifier encoder following from external VFDs or equipment.

- High speed registration – Easily adjust for variation in size and position of incoming product with mark detection function to improve finished product quality.

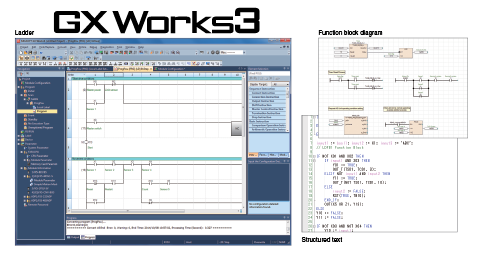

- Single software environment – Configuration, programming, and diagnostics are fully integrated into GX Works3.

- Graphical interface – Easily configure a system and set parameters in GX Works3.

- Multiple programming languages – Multiple IEC 61131 programming languages are supported, and can even be used in the same project simultaneously. This flexibility allows the user to program in the most efficient manner for their application.

- Motion setup tool – GX Works3 eliminates the need for additional software when using the Simple Motion Module.

- Improve machine efficiency – Mitsubishi Electric provides powerful first-class advanced one-touch tuning that sets gains and filters in real-time. Over the life cycle of the machine, continuous tuning optimizes gains to minimize settling time and eliminate cumulative errors. As the machine ages, system longevity and machine efficiency are improved.

- Easy system synchronization – Servo synchronization is easy with the graphical mechanical editor. Simply drag and drop mechanical devices on the screen and set related parameters such as speed change gear ratio or clutch control type to drastically reduce configuration time of synchronous systems.

- Advanced synchronous control – Applications requiring camming will benefit from the simple cam function, which makes it easy to enable synchronous control with 3 different cam control modes. Control via software rather than mechanical components reduces maintenance and commissioning time, and increases machine flexibility.