Mitsubishi Electric Achieves Guinness World Record for Fastest Robot to Solve a Puzzle Cube

July 3, 2204

A project team of young engineers from Mitsubishi Electric Corporation beat the previous record by 0.075 seconds using a robot equipped with high-speed, high-precision factory automation equipment and control technology.

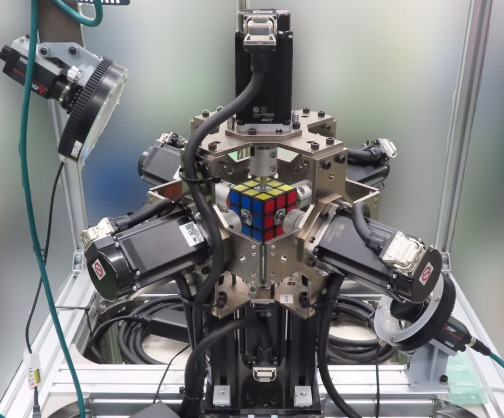

Mitsubishi Electric Corporation recently announced that it had been awarded a GUINNESS WORLD RECORDS™ title on May 21, 2024, for the fastest robot to solve a puzzle cube using the TOKUI Fast Accurate Synchronized motion Testing Robot (TOKUFASTbot). The previous record of 0.38 seconds was trumped by TOKUFASTbot’s time of 0.305 seconds.

Mitsubishi Electric Corporation reports that a young project team worked to set the world record as a demonstration of the technical capabilities of high-tech motors, power semiconductors, and related products developed and manufactured by its Component Production Engineering Center. Established in 2016, this center has produced technologies that achieve high-speed and high-precision windings that are key to increasing the productivity and efficiency of motors used in many of the products.

The TOKUFASTbot can perform a 90° rotation time of 0.009 seconds thanks to the rotation mechanism built by Mitsubishi Electric’s compact, high-power, signal-responsive servomotors and a color-recognition algorithm developed with proprietary AI technology. The high-speed signal connection and inter-device control are achieved through the use of the servomotors as well as a PLC, industrial PC, touch panel display, and cameras.

“The Mitsubishi Electric Automation team is immensely proud of our parent companies’ efforts to accomplish this feat. This Guinness World Records certificate was awarded due to intelligent programming and engineering using several automation components, including our MELSERVO-J5 servomotors, which demonstrates the performance of our products,” said Dan Zachacki, product manager (servo) at Mitsubishi Electric Automation, Inc.

More Information

To learn more about this story, visit https://www.mitsubishielectric.com/news/2024/0523.html.

Related Story

Mitsubishi Electric and Dispel to Expand Operational Technology Security Business

Mitsubishi Electric Corporation announced that it has signed an agreement with Dispel LLC, a developer and distributor of secure remote access and operational management solutions, to expand its operational technology (OT) security business through marketing and technical development.