LogiMAT 2023: Interroll Presents New High Performance Conveyor Platform (HPP) for Courier, Express and Parcel Service Providers

April 28, 2023

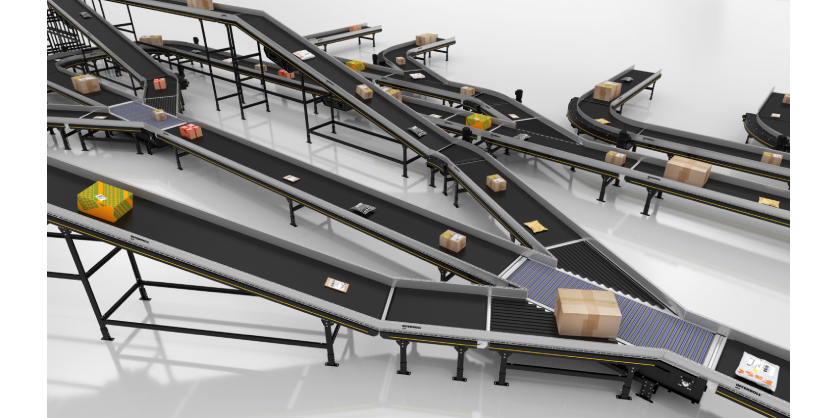

Following the example of its globally successful Modular Conveyor Platform (MCP), Interroll is launching a modular conveyor solution that meets the specific robustness and throughput requirements of courier, express and parcel (CEP) service providers. The new High Performance Conveyor Platform (HPP)—a powerful addition to Interroll’s sortation solutions in particular—can significantly increase large and small distribution centers’ productivity, capacity and energy efficiency.

As part of Interroll’s comprehensive platform strategy, the HPP primarily uses proven technical products that have already proved themselves hundreds of thousands of times with users. The new offering will be on display for the first time from April 25–27, 2023, at Interroll’s LogiMAT trade fair stand (Hall 1, Stand K41) in Stuttgart, Germany, where visitors will also be able to experience the company’s platform strategy for material flow solutions in a playful way.

The popularity of online shopping is generating an ever-increasing quantity and variety of goods that need to be transported and sorted in the distribution networks of CEP service providers worldwide. The number of parcels processed by corresponding conveyor and sorting systems in the largest 13 countries is set to rise from 159 billion in 2021 to 256 billion in 2027. Interroll’s automatic sortation solutions have played a key role in mastering these material-handling challenges for over 20 years. More than 500 sorters have been deployed globally by industry leaders such as Amazon, DHL, FedEx, UPS, Hugo Boss, Inditex (ZARA) and Zalando as well as postal services.

“For our innovation course, we have been consistently leveraging the benefits of our platform strategy for many years. The latest example is the new High Performance Conveyor Platform (HPP), which we developed based on our many years of industry expertise in the CEP market. It offers system integrators and courier, express and parcel service providers important additional value in achieving their business goals,” explains Jens Strüwing, Executive Vice President Products & Technology at Interroll.

“In addition to the maximum flexibility and proven product quality of this modular system of freely combinable conveyor modules, these are above all the energy efficiency, ease of use and speed with which automation projects can be implemented. In combination with a corresponding service offer, productivity in large and small parcel centers can be significantly increased in this way—for new installations, but also for retrofit projects.”

Jens Strüwing, Executive Vice President Products & Technology at Interroll

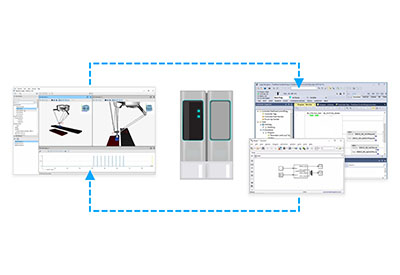

Fast project implementation through digital processes

The Interroll Layouter can be used, for example, to clearly design and plan complete HPP system concepts on a computer and implement them virtually. The solution drastically reduces the effort, planning time and, therefore, project duration. It also makes for more informative and greatly simplified presentations and decision-making processes for users. At the same time, the standardized modules reduce the time required for installing and implementing solutions.

What’s more, the seamless processing of data from the Interroll Layouter in enterprise resource planning (ERP) systems at production sites enables short delivery times. As with Interroll sorters, customers are supported with consistent and agile project management.

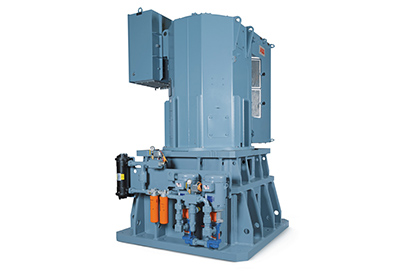

The new conveyor platform consists of a large number of standardized line and curve modules that can be freely combined to meet the respective customer requirements. These include, for example, straight conveyor modules and modules for inclines and declines. The rigidity has been increased by one-third compared to the MCP. The robustness of the platform allows loads of up to 50 kilograms per meter, while the maximum conveying speed is 2.5 meters per second.

Depending on the dimensioning and the goods transported, a throughput of up to 10,000 units per hour is possible. The solution can process a huge range of goods to be sorted, including cardboard boxes, small packages, padded envelopes, manila envelopes and polybags.

Energy-efficient drive technology, simple start-up and maintenance

Depending on customer needs, conveyors based on this platform are driven by gear or drum motors, which offer an efficiency of around 90 percent and enable a quiet and productive working environment with very high throughputs. When using conveyor lines with a central drive, the belt is tensioned from just one side, which significantly simplifies startup and maintenance. The design of the side guides is also well thought out in terms of construction.

Thanks to their symmetrical and modular structure, they use only a few standardized components for the left and right conveyor sides. In addition, the overlapping design creates closed transitions from one conveyor line to the next, preventing transported goods from getting stuck at the transitions.

Module integrates conveying and sorting

The functional core of the HPP is the innovative Interroll Multibelt Switch (MBS). The module combines conveying and sorting functions in a unique way. By seamlessly overlaying the straight-line and lateral movements, the conveying goods are diverted onto additional conveyor lines at a constant speed in the conveyor either straight ahead or on two sides. This method ensures not only a gentle and safe transport process, but also a very high speed and throughput values of over 10,000 units per hour.

With the Interroll MBS, customers can further increase the capacity of their distribution centers through a higher degree of automation, based on the High Performance Conveyor Platform. This applies not only to conveying presorted goods in the direction of or behind large sorting systems, such as those used in major distribution centers; even in smaller, customer-oriented package centers with few destinations now being constructed in many places, the automation solution can greatly increase work productivity and economic efficiency. In addition, the MBS can be used as a gateway to automatic sorting for applications that need only a few destinations.

The HPP will go into production in Europe in the second quarter of 2023, and in America and Asia in 2024.