New Balluff Proximity Sensors Reliably Detect Objects in Temperatures Up to 230 °C

November 15, 2018

Balluff’s family of high-temperature proximity sensors are designed and tested to provide reliable non-contact object detection in ambient temperatures up to 230 °C/446 °F. This level of protection is required for hot metal stamping, glass manufacturing, steel and aluminum manufacturing, steel forging, steam curing, and other high-temp processes.

Two main features allow these sensors to withstand extreme temperatures: First, the face of each sensor is composed of a heat-resistant LCP (liquid crystal polymer) material; Second, the head of the sensor contains only the passive, non-electronic, components of the device that are less susceptible to heat. The electronic amplifier portion of the sensor is located at the far end of the 5 meter/16 foot connector cable, allowing you to place it outside the high-temperature zone. The cable jacket and insulation, made from heat-resistant PTFE, is specified to withstand the same temperature as the sensor head.

Sensors that have electronics built into the sensor head are usually rated to not exceed 70 °C/158 °F. If your kitchen is hotter, high-temperature rated sensors are better equipped to combat the malfunctioning, failure, and machine downtime that often occur when sensor electronics exceed their rated limits.

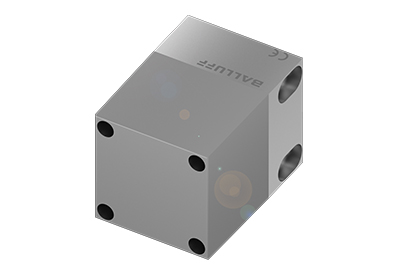

This group is available in M8, M18, M30 tubular housings with an integrated 5 meter amplifier connector cable, and in a block style with a detachable 10 meter/33 feet amplifier connector cable (ordered separately).

Key Features:

- Ideal for high ambient temperatures up to 230 °C/446 °F

- Sensor face composed of high-temperature LCP

- Extended 5m/16ft. amplifier-connector cable keeps electronic components at a safe distance from hot process areas

- Cables composed of heat-resistant PTFE

- M8, M18, M30 and multiple block-style housings available

- Standardized M12 connection for simple installation and replacement