ABB and Gravitricity to Collaborate on Energy Storage Systems Using End-Of-Life Mine Shafts and Hoist Technology

January 8, 2024

ABB will assist Gravitricity in accelerating the technology towards commercial adoption

- Gravitricity has developed GraviStore, an innovative gravity energy storage system that offers some of the best characteristics of lithium-ion batteries and pumped hydro storage

- ABB will assist Gravitricity in accelerating the technology towards commercial adoption

- For ABB’s mining customers, this partnership brings new sustainability opportunities beyond shaft decommissioning

ABB has signed an agreement with UK-based gravity energy storage firm Gravitricity to explore how hoist expertise and technologies can accelerate the development and implementation of gravity energy storage systems in former mines.

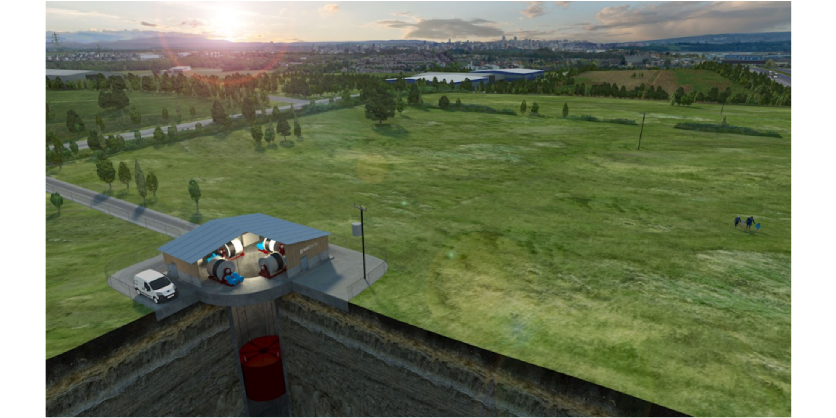

Gravitricity has developed GraviStore, an innovative gravity energy storage system that raises and lowers heavy weights in underground shafts – to offer some of the best characteristics of lithium-ion batteries and pumped hydro storage. Future GraviStores will store more than 20MWh, providing long-duration storage and rapid power delivery to network-constrained users and operators, distribution networks and major power users.

Unlike batteries, the Gravitricity system can operate for decades without any reduction in performance. Gravitricity has already proven the system with a scale demonstrator and is exploring the potential to deploy their groundbreaking technology in decommissioned mines worldwide.

As a market leader for mine hoists with a large installed base of more than 1,000 hoist solutions worldwide, ABB will collaborate by providing research and development, product development and engineering teams specializing in the design, engineering and operations of mine hoists and mechanical, electrical and control technologies for hoisting.

“As the world generates more electricity from intermittent renewable energy sources, there is a growing need for technologies which can capture and store energy during periods of low demand and release it rapidly when required,” said Martin Wright, Gravitricity’s co-founder and Executive Chairman. “Our GraviStore underground gravity energy storage uses the force of gravity to offer some of the best characteristics of lithium-ion batteries and pumped hydro storage – at low cost, and without the need for any rare earth metals.

Martin Wright, Gravitricity’s co-founder and Executive Chairman

“We are already seeing significant interest from mine operators in Europe, India and Australia and this partnership with ABB – with decades of electrification and mine hoist system expertise – will help us accelerate our ambitious commercialization plans. I am delighted we are working in tandem.”

The Memorandum of Understanding (MoU) agreement is an important step in ABB’s ambition to further develop its lifecycle service business by collaborating with companies providing adjacent and value-adding technologies.

“ABB has 130 years of history with mine hoists, since we first electrified one in Sweden in the 1890s, but this collaboration with Gravitricity shows how we can continue to diversify and adapt our technologies,” said Charles Bennett, Global Service Manager, Business Line Hoisting, ABB Process Industries. “We are eager to progress with our collaboration and explore the possibilities as we become part of the next generation of renewable energy storage systems and make use of mine shafts that are no longer in service.”

Charles Bennett, Global Service Manager, Business Line Hoisting, ABB Process Industries

Gravitricity will bring specialist expertise in grid compliance and control systems and the teams will work together on feasibility studies to understand the application of existing hoisting technology in gravity energy stores. ABB will also offer mining industry consultation and work to identify suitable sites and shafts for the deployment of GraviStore.

The decommissioning of mine shafts is a costly and time-consuming process for mining companies. By repurposing disused mine shafts for energy storage, mine shafts can fill a productive function for up to 50 years beyond their original lifetime, and can mitigate decommissioning costs, while simultaneously creating new job opportunities and contributing to the green energy transition.

ABB is a leader in developing world-class hoisting solutions. As a supplier of complete mine hoist systems, customers can benefit from low lifecycle cost, high reliability and system availability, short project execution time, and a single source of supply for complete systems, including service and spare parts.

ABB is a technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. The company’s solutions connect engineering know-how and software to optimize how things are manufactured, moved, powered and operated. Building on more than 140 years of excellence, ABB’s ~105,000 employees are committed to driving innovations that accelerate industrial transformation. www.abb.com

More Information

Related Story

ABB Contributes to New Report Showing How Industry Can Reduce Global Carbon Emissions By 11% By 2030 While Saving $437 Billion Annually

As industry is facing the unprecedented challenge to meet global decarbonization targets while addressing growing demand, a new report from the Energy Efficiency Movement (EEM) demonstrates how businesses can start acting immediately. The EEM is a global forum founded by ABB, and now consisting of more than 400 organizations, that shares ideas, best practices and commitments to create a more energy-efficient world.