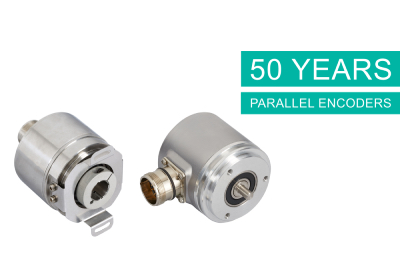

50 Years of Bit Parallel Encoders from POSITAL

May 24, 2022

Encoder-maker POSITAL remains committed to supplying customers with absolute encoders with bit parallel communications interfaces. “Rotary encoders with parallel interfaces have been sold under the FRABA and POSITAL brands since 1972,” comments Christian Fell, leader of POSITAL’s North American operations.

Absolute encoders with parallel interfaces have always offered excellent dynamic response. However, the resolution of these encoders depends on the number of conductors in the connecting cable, resulting in a trade-off between resolution and cable size. As the performance of serial interfaces improved, parallel interfaces became less popular, and this interface has been dropped from many manufacturers’ catalogues. Nevertheless, with many parallel interface encoders still in service, there is a modest but steady demand for plug-compatible replacements.

POSITAL’s ability to supply this low-volume niche market with cost-effective products is directly related to its modular design philosophy and flexible “minimum order quantity: one” (MOQ1) manufacturing system.

Fell explains: “Our encoders are designed as assemblies of inter-changeable components. Except for a few specialized parts, our parallel interface encoders have most of the same components as encoders with serial, fieldbus, or industrial Ethernet interfaces. As long as we can source the necessary parts, we will continue to supply this market.”

POSITAL absolute encoders with parallel interfaces are based on the company’s optical measurement technology and are available in single (up to 16-bit resolution) and multi-turn (up to 25-bit output) configurations. Output is managed by an embedded microcontroller so that many coding options, including Binary, Gray and excess Gray are supported. Custom codes – such as Petherick, or those used in cam or end-switch type applications, can be implemented through software, making it possible to reproduce the functional characteristics of older sensors used in long-lived applications like public transport or machine tools. Like other POSITAL encoders, these devices are available with a wide range of options for housing material, flange design and shaft configuration (including through hollow).

PS: POSITAL will be exhibiting at AUTOMATE in Detroit (June 6-9) – Booth 2557. Feel free to stop by and have a fun ‘tech talk’ with Andy Zou (andy.zou@fraba.com). After a successful career with FRABA in Asia (where he helped to open the Shanghai office), Andy has joined the North American operation just a year ago. His mandate includes developing new market segments for FRABA and its brands POSITAL (encoders) and UBITO (Wiegand technology – energy harvesting and IIoT wireless sensors). The pandemic has limited Andy’s ability to get out and meet you all, so AUTOMATE will be a great opportunity to get acquainted!

To learn more about POSITAL’s absolute encoders, click here