From Factory Floor to Cloud: How Smart Sensors are Powering the Industrial IoT Revolution

October 14, 2025

Sensors have evolved from simple detection tools to intelligent data sources that drive smarter decisions. They are no longer just watching; they are communicating, diagnosing, and optimizing.

The Eyes and Ears of Automation

Sensors are the first line of awareness in any automated system. They detect the presence or absence of objects, monitor environmental conditions, and trigger precise actions that keep production lines moving. Whether it’s a photoelectric sensor spotting a product or a proximity sensor confirming alignment, these devices ensure that operations run smoothly and safely. They also play a critical role in quality control, helping manufacturers reduce errors and maintain consistency across batches.

Smarter Data with IO-Link

The introduction of IO-Link technology has transformed how sensors interact with industrial networks. Instead of sending basic on/off signals, IO-Link–enabled sensors deliver rich diagnostic data that can be used to monitor machine health and performance.

Key advantages include:

- Remote configuration and monitoring

- Automatic device recognition and replacement

- Real-time feedback on temperature, light intensity, and more

This level of intelligence allows operators to catch issues like wear, contamination, or misalignment before they escalate into costly downtime.

Real-Time Decisions, Less Downtime

Sensor data empowers teams to make fast, informed decisions. For example, if a sensor detects a missing part, the system can halt production instantly to prevent defects. When hundreds of sensors are connected across a machine, diagnostics become faster and more accurate, reducing troubleshooting time and improving overall efficiency.

Predictive maintenance becomes possible when sensors continuously report on machine conditions, allowing teams to schedule repairs before failures occur.

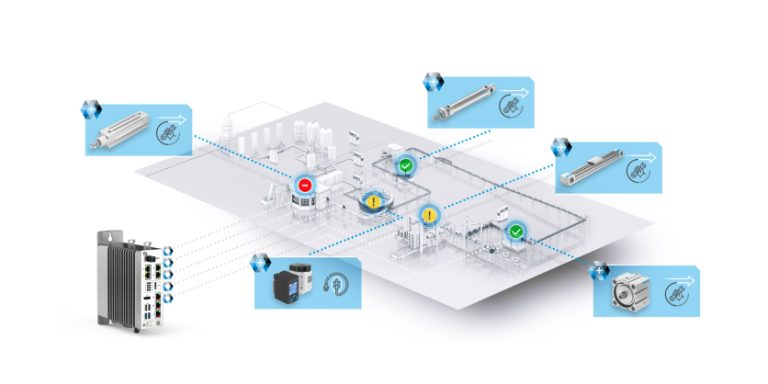

Connecting Machines to the Cloud

Sensors are the bridge between equipment and digital platforms. Their data feeds into cloud-based dashboards, enabling remote monitoring and analytics. This connectivity supports adaptive production systems that learn and improve over time, making factories more agile and responsive.

As industrial IoT continues to grow, sensors will remain the foundation of smarter, more connected operations.

Future-Proof Your Factory

Investing in smart sensors today means preparing your facility for tomorrow’s innovations. With faster data transmission, built-in connectivity, and seamless integration, IO-Link sensors are ready for AI-driven analytics and next-gen automation.

Even if you’re not using all the data yet, having the infrastructure in place ensures you won’t be left behind.

Ready to Level Up Your Sensing Strategy?

Explore how OMRON’s advanced sensor solutions can help you unlock smarter, more connected manufacturing.

More Information

Sensors for every application, for machines that never stop

Related Story

Unifying Automation: The Key to Smarter, Scalable Industrial Systems

Industrial automation systems often grow into isolated islands of control platforms and industrial protocols. While functional, these setups create inefficiencies, duplicate engineering, capture inconsistent process data, and introduce security vulnerabilities. Maintenance becomes complex, and scaling or integrating technologies like AI is costly. The result: reactive systems that struggle to adapt.