Aufmaster: Measuring Made Easy

How Aufmaster Is Revolutionizing the World of Electrical Companies at Building Sites

February 14, 2023

Recording cable measurements at building sites is a tiresome task: electricians must cut the cables exactly to the required length and document every cut without exception – traditionally using pen and paper. “There must be an easier way,” thought three young entrepreneurs – and so they developed a digital solution called Aufmaster, which saves time and money in equal measure.

“It all began in 2015 in South Tyrol while mountaineering,” recalls Claudius Jehle. The engineer from Ravensburg, Germany, is one of the three brains behind Aufmaster. “While there, I was discussing with my father, Paul, who runs an electrical installation business, and my brother Constantin, a qualified electrician, about how tiresome cable measurements are. In our experience, having to write everything down on paper means that things are often not documented correctly, which makes billing very difficult.”

Claudius Jehle, Engineer

The three mountaineers’ approach to the solution: to invent a device that constantly measures the remaining length of cable on a reel, so that the length that is cut can automatically be calculated and documented. If this data could then be transferred to a smartphone via an app, this would make life a lot easier for electrical companies. The idea for Aufmaster was born. As soon as they got home, the Jehles soldered a prototype and, in the following year, they produced the first measuring devices.

Software Experts for Digitalization

In 2019, Jan Müller and André Wagner joined the team. The two software experts who have known each other since their school days, had already acquired their first experience as entrepreneurs through their own firm. “Together we developed websites for various companies and later logistics software for customers in the car and precision optics industries,” reports Jan. “One day a mutual friend told me about Claudius and his idea for Aufmaster.” With the aim of pushing ahead the digitalization of the project, Jan decided to become part of the Aufmaster story and got his friend and business partner André on board immediately.

Together, the three inventors began to develop an app as well as a web portal for Aufmaster. At the same time, they received their first real-life reports from various customers who had been given the measuring device to try out.

“The response from companies was amazing,” André explains. “We worked out that with Aufmaster, we could reduce the cost of measuring and administration by around 30 per cent. Electricians at building sites no longer have to fill in forms by hand, which then have to be laboriously decoded at the office. This saves work and avoids the embarrassment of incorrect billing.”

André Wagner, Software Expert

A Strong Sales Partner

However, it soon became apparent to the creative brains that such a device – particularly in connection with an app and smartphone or tablet – represented something very new to the average craftsman. “We were aware that, on our own, we’d only have limited success,” explains Jan. “We needed a strong partner at our side to help us access the right customers.” The Aufmaster team found such a partner in HELUKABEL, who were also enthusiastic about the idea. Since then, the company has been providing valuable support with sales and marketing. There are also plans to create a joint product database and attach Aufmaster QR codes to HELUKABEL drums so that the app automatically recognizes the respective cable type.

By the autumn of 2022 everything was in place: the first professionally manufactured batch of Aufmaster devices were shipped to customers and the web portal was ready to use! The project reached its first major milestone. But this certainly won’t be its last one, André points out: “Our big vision is namely: ‘an Aufmaster in every toolbox’”. The three young entrepreneurs are fully aware that there’s still a long way to go. “We’re convinced that our idea has the potential to spread across the whole industry – the benefits speak for themselves,” argues André. “And the cooperation with HELUKABEL provides us with the right prerequisites for sustained success in the market.”

What is Aufmaster?

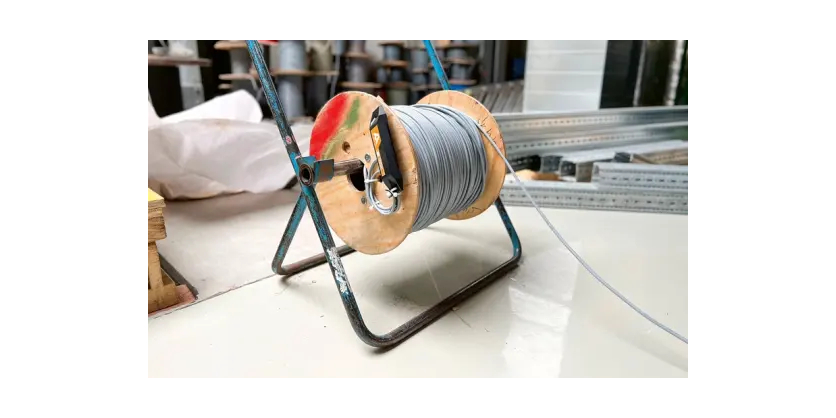

Aufmaster is a system comprising of software and a digital measuring device that automatically records and documents the length of cables cut at building sites. It involves connecting the device to the back end of the reeled cable using two clips. Whenever an electrician cuts off a piece of cable, the exact length of the cut is automatically transmitted to an app on their tablet or smartphone. From there the data is transmitted over the Internet to the respective customer account at the electrical company.

Using the software allows diverse projects with multiple measuring devices attached to various cable reels to be controlled and managed, and the calculation of the cut lengths to be tracked and documented in real-time. The most significant benefit is the reduced time and energy spent on recording measurements and invoicing – and hence the lower costs. In addition, it reduces the risk for errors, which results in fewer complaints. Find out more at www.aufmaster.de

Related Story

Why Use VFD Cables? HELUKABEL Answers

The current NFPA guidelines require RHH, RHW, RHW-2, XHH, XHHE or XHHW-2 insulation for use inside the motor’s control panel or cabinet, but the expectation is this requirement will move to include cable used in external wiring of VFD applications in the upcoming years

Why Use VFD Cables? VFD cables are a critical component to extend a motor’s life cycle within a VFD system. Three areas where VFD cables set themselves apart from traditional tray-rated power cables are: