New Edition of ISO 14119 Describes the State of the Art – Normative Guidance for Safety Gates

September 29, 2025

New Edition of ISO 14119 Describes the State of the Art – Normative Guidance for Safety Gates

ISO has published a new edition of ISO 14119 “Safety of machinery – Interlocking devices associated with guards”. The established standard sets out principles for the design and selection of safety gate systems. The requirements for accessible safety gates have now been specified. Design engineers should familiarise themselves with the new features early, so as to guarantee their machines are also CE-compliant in the future.

ISO 14119 has classified interlocking switches and regulated the specifications for installing guards since 2013. The new, third edition of ISO 14119:2024 specifies the procedure for safeguarding accessible gates: if there is a risk that machinery will start up unexpectedly, devices such as a manual reset function or presence detection devices must be present. There should also be suitable means for escape and emergency release.

Specifically, the new edition requires the use of key transfer systems and the series connection of electromechanical contacts (number of devices that can be connected in series), in order to increase the safety of accessible safety gates. The two subjects were previously described in ISO TR 19837 (interlocking systems) and ISO TR 24119 (series connections). These new features now form part of ISO 14119, in the new Clause 6.3.

New standard means automatic safety

“The new version has not yet been published in the Official Journal of the EU. However, there will be no more changes to the content of the new version,” explains Jan Franck, member of the standards team at Pilz GmbH & Co. KG. The automation company was involved in developing the new edition.

“We therefore recommend that you now use ISO 14119:2024 as a basis for designing safety gates, as it represents the current state of the art. That way you’re automatically on the safe side,” advises the Pilz expert.

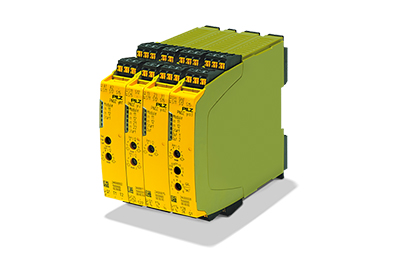

With its safety switches and safety locking devices, Pilz will meet the requirements of the new edition. As a result, the company supports design engineers who develop systems that are standard-compliant and future-proof.

More Information

Safety switches with guard locking devices

Related Story

Training Courses on Plant and Machinery Safety from Pilz

Plant safety is vitally important for the safe operation of technical plants. As a machine manufacturer or operator you are legally obliged to ensure the safety of plant, machinery and devices. Training courses teaches you to identify risks and avoid accidents. Further training for safety officers and employees is the key to success here. With this knowledge you can operate plants more efficiently and safely carry out maintenance work. By integrating plant safety into your company you are demonstrating responsibility and increasing the confidence of authorities, employees and the public. Plant safety also contributes towards the prevention of environmental pollution and damage.