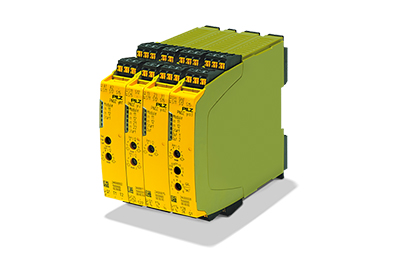

Pilz: myPNOZ, the New, Modular Safety Relay

February 16, 2021

The new modular safety relay myPNOZ is produced individually according to your requirements in batch size 1. An easy-to-use device that’s flexible in application and boasts clever features, it ensures reliable monitoring of your safety functions.

Three steps to your modular safety relay

You create

With the user-friendly myPNOZ Creator, you simply create your individual myPNOZ. You choose the required safety functions, and myPNOZ Creator puts the ideal hardware together. You can check your configuration with the simulation function. If everything fits, your myPNOZ is ordered with just a few quick clicks.

Pilz builds

Each myPNOZ is tailor-made pre-assembled by Pilz in batch size 1 according to your individual configuration. They also set the parameters to suit your specifications, e.g. with regard to the start type or time delay for you. Your modular relay will be sent to you following a system test.

You install

myPNOZ is quick and easy to install. You’ll receive your ready-to-use myPNOZ ‘ready for Plug and Play’. No software is required for commissioning. And the time and effort required for wiring has also been significantly reduced.

Product Features

The modular safety relay impresses due to tailor-made safety and its clever product features. It consists of a head module and a maximum of eight expansion modules and ensures safe monitoring of 2 to 16 input functions such as emergency stop, safety gates, safety light barriers, two-hand IIIA/C controls and enabling switches.

- Higher-level safety function and power supply using the head module

- Four input modules, four output modules and four input / output modules available

- Monitoring of machine parts in independent safety zones

- Module connection using a bus plug

- Two safety inputs per input module, AND / OR-linked as an option

- Output modules with relay or semiconductor outputs with / without time delay

- Module expansion and replacement when installed

- Diagnostics via LED display

Five reasons for using myPNOZ

You cut costs – pay for what you need

From the multitude of available modules, you choose or myPNOZ Creator selects only those with the functions you really need. If your requirements change, myPNOZ can be modified and expanded at any time – giving you maximum flexibility.

You save time – quick and easy commissioning

You will receive your myPNOZ from us in a pre-assembled, adjusted and tested state. Ready for ‘Plug and Play’ commissioning without additional software and without complicated wiring.

You increase your plant’s availability – switch off where it matters

myPNOZ allows you to monitor plant sections independently of one another in separate safety zones. OR links between input functions can also be implemented as an option.

You prevent faults – zero programming knowledge required

You define the required safety functions in myPNOZ Creator. myPNOZ Creator automatically selects the ideal hardware and the corresponding sequence of the modules.

You save space – fewer modules and a narrow design width

Each input module monitors two safe input functions, which means you need fewer modules. What’s more, myPNOZ impresses with narrow widths of 12.5 mm or 17.5 mm.

How to use the modular safety relay myPNOZ

Whether you’d like to protect a small application with just two safe input functions or larger applications with up to 16 input functions. The modular relay myPNOZ covers a wide range of applications and can be used on almost any automated plant. Its simple handling and modular design mean the modular relay is flexibly adaptable and expandable at all times.

TruStability series deployed by Surrey Sensors Ltd for testing Formula 1 and unmanned aerial vehicle applications.

TruStability series deployed by Surrey Sensors Ltd for testing Formula 1 and unmanned aerial vehicle applications.