Kollmorgen Expands its Line of Certified Explosion-Proof Products with New ATEX and IECEx/cETLus Status for Goldline High-Voltage Servo Motors

August 3, 2023

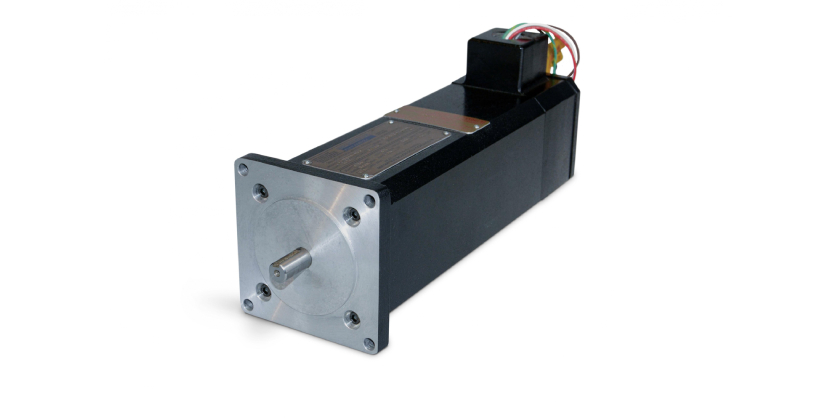

For hazardous locations that require use of an explosion-proof motor, Kollmorgen’s Goldline EB series of ATEX Certified and IECEx/cETLus Listed servo motors now includes the 480 Vac Goldline EBH.

Kollmorgen, a global leader in motion control systems, has announced ATEX certification and IECEx/cETLus listing for the explosion-proof Goldline EBH 480 Vac servo motor. These new explosion-proof approvals for the high-voltage Goldline EBH servo motor exemplify Kollmorgen’s commitment to advancing the state of the art in motion control and meeting the most demanding application requirements.

The high-voltage Goldline EBH servo motor joins a broad selection of Kollmorgen explosion proof motors certified and listed according to UL, ATEX, IECEx and/or CSA standards. Explosion proof motors are required in hazardous locations where flammable gases, mists or vapors may exist in explosive or ignitable concentrations. Such environments are often found in mines, oil & gas refineries, textile mills, and industrial paint booths.

For high-voltage applications in hazardous locations, Goldline EBH servo motors offer speeds up to 7,500 rpm with exceptionally high torque density for maximum performance in a minimal installation footprint. Rugged resolver feedback and a built-in thermostat support reliable operation under harsh environmental conditions.

Goldline EBH servo motors in frame sizes 1 – 6 join other explosion-proof motors in the Goldline EB family that meet ATEX/IECEx standards, and more specifically CE 0081 Ex II 2 G Ex d IIB T3 Gb –40ºC ≤ Ta ≤ 40ºC.

This classification indicates that the motors are suitable for use in any above-ground industry where easily ignited gases such as ethylene are likely to be present in the atmosphere for 10 to 1,000 hours/year during normal operation (Zones 1 and 2). Kollmorgen applies a flameproof method of protection to the motor so that any internal ignition is contained within the motor housing without the possibility of escape into the external atmosphere. The maximum surface temperature of the motor under fault conditions is 200°C.

More Information

Explosion-proof Goldline EBH high-voltage servo motor

Related Story

Kollmorgen Express Delivery Significantly Shortens Lead Times for the Company’s Most Popular Motion Products

Kollmorgen, a global leader in motion control systems, has announced the launch of Kollmorgen Express Delivery. This new designation identifies highly popular motion products — including some of the most-requested configurations and options — that Kollmorgen is ready to deliver within an accelerated timeframe.