Nexen: Zero Backlash Geared Bearings

June 19, 2019

Unlike some cam driven systems, the Precision Ring Drive Systems can start and stop at any incremental position. Users can change the motion profile by simply loading a new servo drive program. The Precision Ring Drive System also allow maximum acceleration or deceleration at any point without the risk of damage.

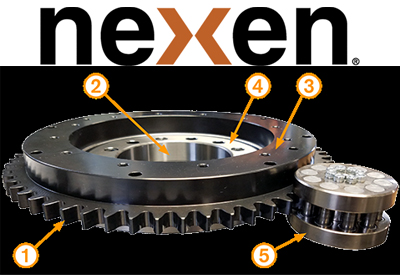

Based on Nexen’s innovative Roller Pinion technology, the Roller Pinion System Geared Bearing (RPS-GB) comes complete with a precision zero backlash gear mounted and dialed in on a precision grade high capacity bearing.

With many possible sizes and gear ratios, all with zero backlash, the Nexen Geared Bearing can be incorporated into any precision rotary motion control application.

![]() HIGH PRECISION RPS GEARS

HIGH PRECISION RPS GEARS

• Zero backlash

• Extremely high accuracy

• Lube free operation

![]() LARGE OPEN CENTER

LARGE OPEN CENTER

• Mount equipment & cabling through center opening

![]() MOUNTING OPTIONS

MOUNTING OPTIONS

• Threaded hole mounting

• Through hole mounting

• Piloting options

![]() HIGH CAPACITY CROSS ROLLER BEARING

HIGH CAPACITY CROSS ROLLER BEARING

• Supports significant loads

![]() DRIVE FLEXIBILITY

DRIVE FLEXIBILITY

• Pinions compatible with common gearboxes

For more information: https://www.nexengroup.com/nxn/products/prod-nav/lp/Geared+Bearings