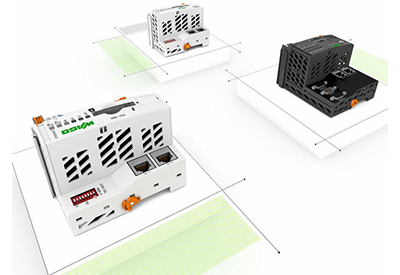

WAGO: Controllers (PLCs)

July 16, 2021

Optimum performance and availability for machines and equipment: Thanks to their ultra-high performance, low power consumption, numerous interfaces, space-saving design and high level of reliability, WAGO’s user-friendly programmable logic controllers (PLCs) are cost-effective automation solutions for numerous applications.

The Benefits of WAGO PLCs for You:

- – Programmable with e!COCKPIT (CoDeSys 3) and CoDeSys 2

- – Fieldbus-independent – support for all standard fieldbus protocols and ETHERNET standards

- – Scalable computing power from fieldbus controllers to PFC100 and PFC200 Controllers

- – Ideal combination with the WAGO I/O-SYSTEM 750: 500+ modules for maximum flexibility and functional variety

- – Also for use in extreme environments