Versatile POSITAL Displays for On-Site Measurements

December 16, 2021

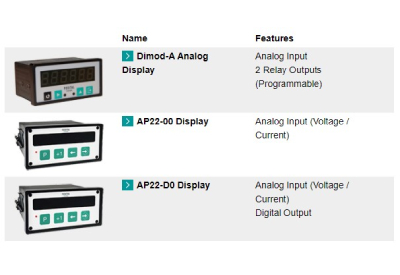

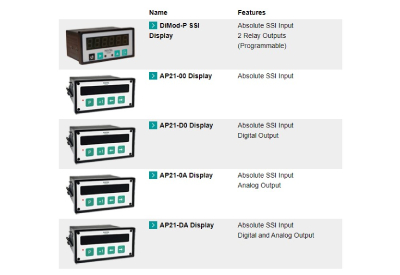

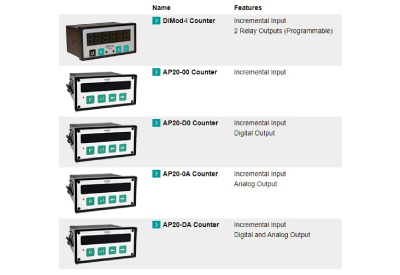

POSITAL’s digital display units offer a cost-effective way to provide direct measurement readouts. Depending on the type of sensor, the display units can be ordered with Analog, SSI or incremental inputs. Thanks to their compact size and sturdy construction, they can be used for machine setup tasks or as a cost-effective way of monitoring machine status right on the factory floor. Limit warnings or cam-follower functionality can also be displayed.

All Digital Displays

-

- •Connect to Encoders, Inclinometers or Linear Sensors

-

- •Analog, SSI or Incremental Input

-

- •Digital or Analog Output

-

- •Easy Integration to more Complex Control Systems

Displays and counters

POSITAL displays are designed to connect directly to POSITAL’s IXARC rotary encoders, TILTIX inclinometers, LINARIX linear sensors and provide a direct readout of position, rotational speed or angular displacement

| Analog Interface | SSI Interface | Incremental Interface |

|

|

|

For more information, visit POSITAL here