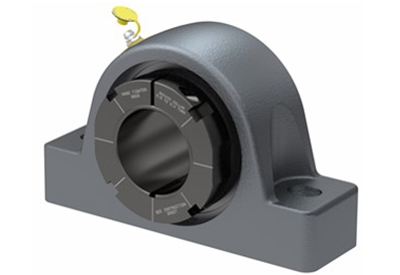

Regal Introduces the Klamploc Adapter Lock for Sealmaster Spherical Bearings

January 14, 2020

Regal Beloit Corporation, a leading manufacturer of electric motors, electrical motion controls, power generation and power transmission components, announces the release of the new Klamploc adapter lock for Sealmaster mounted unitized spherical roller bearings (USRB).

The Klamploc adapter lock was designed to simplify the installation process while improving shaft lock reliability. It accomplishes these goals with two unique design features.

The first feature includes key installation steps that are written on the lock collar. Regal always recommends fully reading the installation instructions prior to attempting an installation. Often, after bearings are removed from their boxes prior to installation, the boxes and the installation sheets get discarded by users. Or, the sheets might be reviewed ahead of time, but the installation specifications do not get memorized or are unavailable when needed at a job site. Because the Klamploc adapter has installation steps clearly marked on its collar, the installer can simply read the specs from the bearing itself.

The second key design feature is a split collar with a cap screw to close the split. With the Klamploc adapter, there are neither parts to remove and then install nor parts to bend on the bearing. Other market options require one or more parts to be removed before installation. This not only introduces additional non-value-added steps, but it also creates a situation where these parts, often small, can be lost.

“Still other market options require a tab to be bent down to achieve the final lock, but bent tabs can be subjective,” said Jason Annes, Sr. Product Manager, Regal Beloit. “With the Klamploc adapter, the final lock of the collar is achieved by simply tightening the screw to the specified torque, eliminating the competition’s several steps.”

In addition to offering simplified final locking, the split Klamploc collar has a benefit unique to the industry. When tightening the collar cap screw, the split collar compresses and grips the adapter sleeve, which can provide additional clamp force to the shaft when combined with the properly set adapter lock.

Sealmaster USRB bearings with the Klamploc adapter lock have launched in bore sizes of 5 inches and below. Sizes above 5 inches will be launched in 2020. Additionally, a spanner installation tool is available. This tool, when used with a half-inch drive breaker bar, speeds up the installation process further by tightening the collar in one step, rather than using several blows from a hammer and drift.

USRB bearings with Klamploc adapter lock include the Sealmaster sealing, which helps to keep contaminants out of the bearing in the toughest and dirtiest situations. USRB bearings can be found in aggregate process, unit material handling, air handling, agriculture, metals and mining, and other industrial applications.