Nidec Launches SynRA, for the US Market, the World’s First Aluminum Cage-equipped, High-efficiency Synchronous Reluctance Motor that Achieves IE5, the Highest Level of the IEC Standard

June 30, 2022

Nidec Corporation recently announced that it has launched for the US market SynRA (Synchronous Reluctance Motor with Aluminum Cage Rotor), the world’s first aluminum cage-equipped, high-efficiency synchronous reluctance (SR) motor that combines an SR motor with the cage-type induction motor’s basic principles.

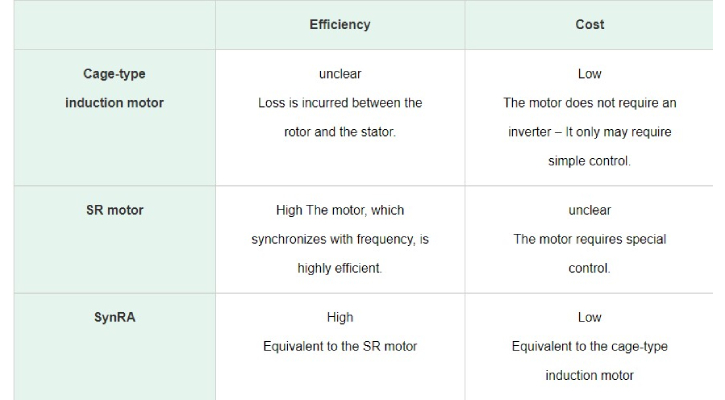

The cage-type induction motor, used as a general-purpose motor for industrial applications, can be activated when connected to a commercial power supply. In addition, the motor, which does not require an inverter (the device to control rpm), does not cost a lot to introduce, and this is why it is used in fans, pumps, compressors, cranes, elevators, and many other industrial machines. Furthermore, the cage-type induction motor can be operated with a simple and inexpensive V/F converter*1 for inverter-based variable-speed products such as air conditioners and other home appliances. This is why the cage-type induction motor is used for a wide range of constant- and variable-speed applications. On the other hand, the motor structurally generates a rotation gap (loss) between its rotor and stator, resulting in less efficiency compared with the SR motor, which is described later.

Thanks to a special reluctance design adopted for its rotor (by incorporating the “cage structure” of the cage-type induction motor), Nidec’s SynRA rotates as an induction motor when activated, and spins in synchronization with frequency during operation. This way, the motor produces less loss and achieves higher efficiency than does the cage-type induction motor. In addition, when using a controller to generate a higher efficiency, the SynRA only requires a simple V/F open-loop control*2 unlike conventional SR motors, which need vector control or precise control parameters for that purpose. Nidec’s SynRA has been certified as an IE5 product – the highest level of an international high-efficiency standard – and verified to be made into a product inexpensively. These facts raise expectations for the SynRA to replace existing cage-type induction motors in the future.

Nidec Group stays committed to offering revolutionary solutions for energy-efficient motors to suppress electricity consumption, and contribute to curbing environmental burdens.

*1. V/F converter: A device to convert voltage (V) into frequency (F), and vice versa. While many electric signals are outputted in the form of voltage, those signals cannot be conveyed accurately as voltage due to fluctuations in the transmission system’s amplification and linearity. This is why a V/F converter is used to transform voltage changes into frequency ones, to demodulate transmission signals with an F/V converter later.

*2. V/F open-loop control: A control method to change an AC motor’s speed with an inverter. Despite its simple configuration and easy adjustments, the V/F open-loop control, in general, has a poor controlled response, while still demonstrating a high efficiency with the SynRA.

For more details on the technologies for the synchronous reluctance motor, click here