Kollmorgen Introduces the AKMA Servo Motor to Meet the Demands of Medium- to Heavy-Washdown Applications

May 24, 2023

Company extends its highly regarded AKM™ servo motor portfolio with a new high performance servo motor that delivers durability, cleanability and versatility.

Kollmorgen has launched the AKMA servo motor built specifically for durability, cleanability, and versatility. The motor employs a hardened anodized aluminum surface to offer machine designers a cost-effective hygienic option to stainless steel in medium- to heavy-washdown applications.

The lightweight design of the AKMA motor makes it easy to install and maintain, and its high torque density offers machine builders more performance in a smaller footprint. The motor is ideally suited for precision motion applications in food & beverage processing, and in pharmaceutical & medical packaging operations. The AKMA’s IP69k rating enables it to deliver high performance even in wet and rugged environments, supporting critical applications like tracking and positioning for antenna pedestal systems.

An anodized aluminum surface offers strong resistance to chemicals across a wide pH range. Since the motor’s smoother and hardened surface is more scratch resistant and will not flake like a painted motor, it can be used above the food line. The AKMA’s stainless steel shaft meets functional safety requirements, while its “one-piece” rounded housing structure eliminates the need for a seal between the flange and housing to prevent puddling and water ingress. The AKMA motor also features a vented design to equalize pressure inside and outside for increased OEE and motor durability.

“We are excited to offer the AKMA servo motors to engineers searching for an affordable motor choice in wash-down environments where stainless steel surfaces are not necessarily required,” said Ross McMillan, Vice President of Engineering at Kollmorgen. “Now, it’s possible to balance performance with value and avoid overspending for a surface quality you may not need.”

Ross McMillan, Vice President of Engineering at Kollmorgen

More Information

Related Product

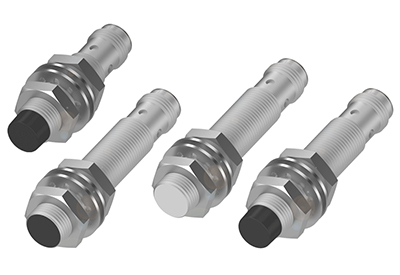

Kollmorgen Debuts EKM Series Brushless AC Servo Motors

Kollmorgen has recently introduced the new EKM series of Enhanced, High-Performance, Brushless AC Servo Motors. EKM Series Motors are Mil-Spec 810E rated and IP67 sealed for duty in harsh environmental conditions. The EKM brushless servo motors feature:

- Industry leading power and torque density

- Ideal for most aerospace and military specifications

- C.O.T.S (commercial off the shelf) solution

- Standard product offering with customization available

- Meets IP67 sealing requirements and is 100% leak-tested housing for further moisture blocking