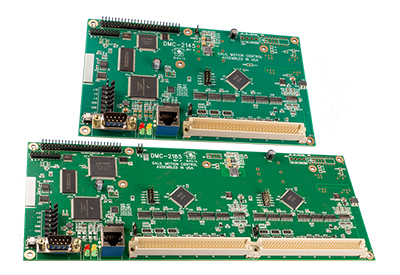

Introducing the New DMC-21×5 Multi Axis Motion Controller From Galil Motion Control

December 21, 2020

The DMC-21×5 is the latest addition to the Econo family and is an easy upgrade path from the long running DMC-21×3 series. The DMC-21×5 utilizes nearly all of the same peripherals as the DMC-21×3 controller, making the transition simple. The main difference between the DMC-21×5 and its predecessor is a state of the art ARM based processor that places its communication, command processing and memory capabilities on par with Galil’s line of current generation motion controllers, while still remaining at the Econo Series price of the DMC-21×3.

The DMC-21×5 is available in one through eight axis formats where each axis is user-configurable for stepper or servo motor operation. Standard programming features include PID compensation with velocity and acceleration feed forward, multitasking for simultaneously running up to eight programs, and I/O processing for synchronizing motion with external events.

Modes of motion include point-to-point positioning, position tracking, jogging, linear and circular interpolation, PVT, contouring, electronic gearing and electronic cam (ECAM).

Like all Galil controllers, the DMC-21×5 controllers use Galil’s popular, intuitive command language allowing for a user friendly interface. Galil’s servo design kit software (GDK Pro) further simplifies system set-up with auto-servo tuning and real-time display of position and velocity information.

For more information, visit HERE.