IDEM Rotary Trapped Key Systems from AutomationDirect

November 4, 2022

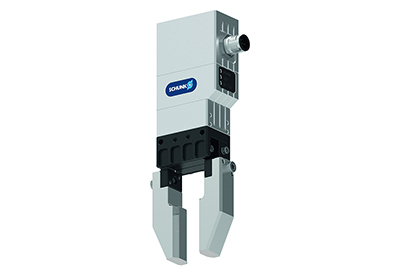

AutomationDirect has added IDEM Skorpion rotary trapped key systems. These safety systems control access to running equipment with locks and rotary keys.

To disable power to machinery and unlock a gate, the key is turned and removed from the control switch. The released key is then inserted into the gate access module to unlock the gate.

Standard and solenoid-locking control switches and associated gate sets (sold separately) are available for one to three stations and provide mechanical safeguarding in partial or full body access versions.

They are rated for safety applications up to Ple/Category 3 according to EN/ISO 13849-1.

The new IDEM Skorpion rotary trapped key systems and accessories start at $210.00 and come with a one-year warranty.

To learn more about the IDEM Skorpion rotary trapped key systems available at AutomationDirect, click here