Fischer Core First Mate Last Break Connectors Ensure Electrical Safety and Mechanical Reliability for Medical Devices

November 29, 2023

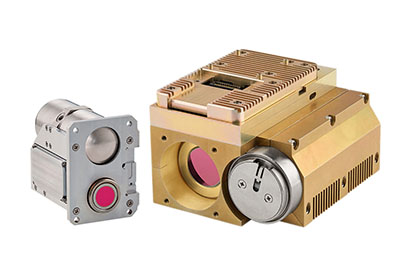

The Fischer Core FMLB connectors and associated cable assemblies are extremely robust and durable, not only mechanically but also in terms of design

Fischer Connectors has released new First Mate Last Break connectors in its low-voltage multipole Fischer Core Series, to offer outstanding levels of electrical safety, mechanical reliability and ease of use for operators of medical devices in compliance with IEC 60601-1.

As its name denotes, First Mate Last Break (FMLB) ensures the permanent ground presence of an electrical system through a longer pin in the plug that “mates first and breaks last” with the system’s receptacle to avoid risky electrical safety conditions. For example, it protects from electrostatic discharge (ESD), allowing any stray voltage to be routed to a safe ground so as to prevent harm to the operator and the voltage-sensitive equipment.

The new Fischer Core FMLB connectors are available in two sizes (‘size 104’ with a 15 mm diameter plug, and ‘size 1031’ with a 13 mm diameter plug), and three mixed low-voltage configurations. Fischer Core 104 A 130 and Fischer Core 1031 A 105 feature 14 pins: 3x 0.9 mm power contacts for a maximum current of 9.5 A for size 104 / 8.1 A for size 1031, and 11x 0.5 mm data contacts (incl. a longer FMLB contact for ground) for 5 Gbit/s Ethernet. As for the Fischer Core 104 A 131 connector, it features 12x power and data contacts of 0.5 mm (incl. the ground/FMLB longer contact) for 4.2 A and 5 Gbit/s Ethernet.

The Fischer Core FMLB connectors and associated cable assemblies are extremely robust and durable, not only mechanically but also in terms of design. They are IP68 sealed, resist autoclave sterilization and corrosion (1,000 hours of salt mist, 5% salt solution, 35 °C), offer long lasting lifecycles with 10,000 mating cycles, and their rugged keying and locking systems ensure safe connections at all times.

“In addition to its robustness, our flagship Fischer Core Series is well-known for its versatility”, explains Alexandra Monchatre, Markets and Products Manager at Fischer Connectors. “Not only in terms of contact configurations, body sizes and materials, but also in terms of locking systems, i.e., push-pull, tamperproof, quick-release and friction fit. This facilitates design engineers’ lives, particularly when it comes to addressing the various needs of medical device users. A single device may use two different types of locking mechanisms depending on whether a connector is used to connect a handpiece or a control console.”

Alexandra Monchatre, Markets and Products Manager at Fischer Connectors

This is precisely the case of the Power-Assisted Liposuction (PAL) System from MicroAire Surgical Instruments, which uses four Fischer Core First Mate Last Break connectors and a 12-feet silicone overmolded cable assembly resisting autoclave. The system’s handpiece uses a connector with a push-pull locking mechanism, whereas the console uses a connector with a friction fit on the same cable assembly to accommodate its end-users’ various needs. In the dedicated case study available on Fischer Connectors’ website, MicroAire’s design engineer explains why they opted for FMLB connectivity:

“We want the ground of the cable to be always on, to mate first, so the system is within a ground presence all the time, and to break last, for signal integrity and electrical safety reasons. Without the presence of ground, we have floating signals which, from a signal integrity point of view, might cause numerous electrical artifacts that are impossible to predict (crosstalk, capacitive coupling, EMI problems, etc.), in addition to risky electrical safety conditions”.

MicroAire’s design engineer

More Information

Full case study: MicroAire Surgical Instruments: Fischer Core First Mate Last Break connectors ensure electrical safety, signal integrity and mechanical reliability

Related Product

Fischer Connectors’ Versatile and Miniature UHD Audio/Video Connectivity Solutions Allow for 18 Gbit/s Data Transfer Speed

Fischer Connectors has released new high-speed connectors and cable assemblies for Ultra High Definition (UHD) audio/video data transfer at 18 Gbit/s in demanding environments, matching the performance speed of HDMI 2.0. Fischer Connectors’ new UHD solutions are available in the flagship Fischer MiniMax™ and Fischer Core product lines with 10’000 mating cycles, 360° EMI protection, different sealing performances from IP68 to hermeticity and sterilization capacities, as well as three locking mechanisms (push-pull, screw, quick-release).