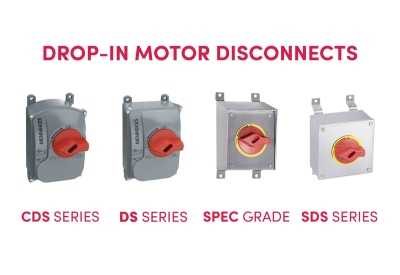

Explore MENNEKES’ Full Range of Disconnect Options

October 11, 2022

It’s never been easier to upgrade your facility with motor disconnect switches that prioritize sanitation, promote safety and minimize installation time with footprint compatibility.

Thanks to an industry-standard mounting pattern, MENNEKES 30A CDS, SPEC Grade and SDS motor disconnects are true drop-in replacements. Offered in non-metallic or stainless steel enclosures, all provide superior functionality and durability in washdown applications. Both the CDS and SPEC Grade units are designed to facilitate liquid runoff, reducing harborage of contaminants.

Let’s explore these three options, so you can pick the best one for your plant environment.

Industry’s First Curved, Non-metallic Motor Disconnect

Our non-metallic, curved-top CDS Series motor disconnect is a safe, reliable way to control power for lockout-tagout (LO/TO) compliance. Featuring a unique water-shedding design, this unit can eliminate standing water, debris and other contaminants. The curved profile prevents top entry wiring to the enclosure, minimizing water ingress and condensation.

Thanks to an impact-modified and chemically resistant enclosure, CDS units are UL Type 4X and IP69K and can withstand frequent, high-pressurized washdown. NSF certified, the 30A CDS is rated 25hp max, satisfying most line motor disconnect requirements.

In terms of mounting options, you can mount CDS switches with provided external mounting feet. When positioned in a vertical orientation, the unit will match Hubbell’s HBLDS3 footprint to facilitate your upgrade process. A second method uses an internal mounting option with Type 4X sealing caps, for compatibility with our legacy disconnects.

The CDS switch offers the option to add a three-position selector switch or other control and push-button devices. This combination enhances operator safety while minimizing parts, mounting space and related costs.

Other features of the CDS Series include:

- •Laser-marked cover for permanent identification — no labels.

- •VALOX® enclosure for superior chemical resistance.

- •Poured-in-place gasket for a long-lasting seal.

- •Standard early-break auxiliary contacts.

- •Captive stainless fixing screws and threaded brass inserts.

- •Highly visible red handle for OSHA LO/TO compliance.

For applications that don’t require a curved design, our DS Series offers many of the same features as the CDS Series. The flat roof profile allows for either top or bottom conduit entry.

Unlocking the Benefits of Stainless Steel: SPEC Grade and SDS Series

Like the non-metallic units, compact, stainless steel SPEC Grade motor disconnects are ideal for critical washdown and cleanroom environments. The 30A SLP model has an industry-standard mounting pattern, making it a true drop-in replacement for non-metallic HBLDS3 motor disconnects.

All SPEC Grade products feature a 15-degree sloped roof for liquid runoff and are UL Type 4X and IP69 rated. Offered in multiple enclosure and switch sizes, other options include blank junction boxes, 1 to 4 position pushbutton enclosures, and 1 to 3 gang combination units with installed receptacles or multiple disconnect switches.

Like the SPEC Grade series, our SDS Series offers the benefits of stainless steel — including repeated washdown cycles and functional reliability in high-traffic, impact prone areas. Offered in two enclosure sizes and rated 30A, 60A and 100A, these units can resist high-temperature washdown and corrosive cleaning agents.

When stainless steel is required but your budget is limited for an upgrade, SDS disconnects are ideally suited to meet your needs. The 30A model has industry standard drop-in mounting for ease of installation. All units have captive cover screws, integral mounting feet with one-inch stand-off and a high visibility LO/TO “clean” handle to shed water and contaminants.

Other SDS disconnect features:

- •Six-pole options for two-speed or reversing motors.

- •IP69K and UL Type 4X ratings.

- •Replaceable DIN rail mounted switch.

- •Early break and late make auxiliary contacts.

- •One-piece punched EPDM gasket.

Both our SDS and SPEC Grade stainless steel motor disconnects are ideal for applications where cleanliness is critical, including food and beverage manufacturing, meat and dairy processing, pulp plants and pharmaceuticals.

To learn more about all of your sloped-top motor disconnect options, check out their brochure