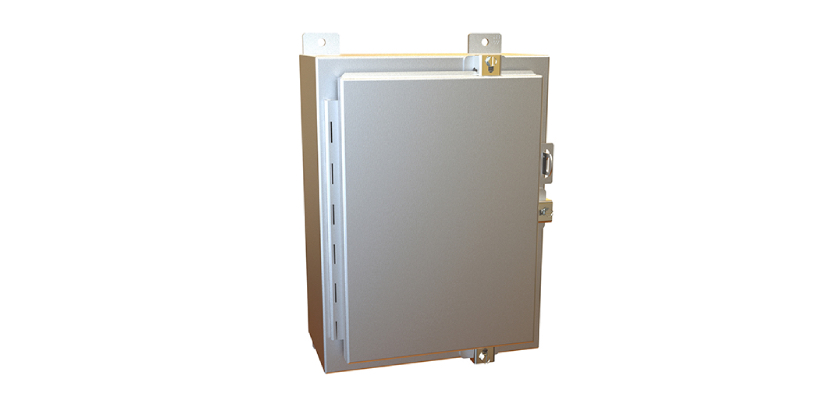

1418 N4 AL Series Type 4X Aluminum Wallmount Enclosure from Hammond Manufacturing

April 27, 2023

Introducing the 1418 N4 AL Series Type 4X aluminum wallmount enclosures from Hammond Manufacturing, designed for use as instrument enclosures, electric, hydraulic and pneumatic control housings, electrical junction boxes and terminal wiring enclosures. These enclosures provide protection where equipment may be hosed down or otherwise be very wet, or in specific applications where corrosion may be a problem.

The 1418 N4 AL Series enclosures are in line with standards such as UL 508 A Type 4, 4X, 12 and 13, CSA Type 4, 4X, 12 and 13, and comply with NEMA Type 4, 4x, 12 and 13, and IEC 60529, IP66.

1418 N4 AL Series Construction

- Formed from 0.081″ (Body) / 0.100″ (Door) Type 5052 H-32 aluminum.

- Smooth, continuously welded seams without knockouts, cutouts or holes.

- Door and body stiffeners are provided in the larger enclosures for extra rigidity.

- Welded brackets provide for enclosure mounting.

- Formed lip on door and enclosure excludes flowing liquids and contaminants.

- Aluminum continuous hinge on door may be removed by pulling the aluminum hinge pin.

- Door is secured with easily operated aluminum clamps.

- Provision for padlocking.

- Seamless poured-in place gasket.

- A removable 12 gauge steel inner panel is included.

- Collar studs are provided for mounting inner panels.

- A bonding stud is provided on the door and a grounding stud is provided in the enclosure.

- A literature pocket is provided for the inside of the door.

Finish

- Cover and enclosure are natural unfinished aluminum.

- Removable inner panel is finished in white powder coating.

More Information

Type 4X Aluminum Wallmount Enclosure

Related Story

RS Partners With Hammond Manufacturing to Provide Custom Electrical and Electronic Enclosures

RS Group plc offers more than 4,900 fully customizable electrical and electronic enclosures from Hammond Manufacturing, in addition to more than 2,900 supporting products.

Enclosures are used to connect and protect two or more electrical and electronic components and devices. They are employed in virtually every commercial and industrial application, and every enclosure gets modified in some way. The simplest enclosures, junction boxes, have just a couple of holes cut for input and output wires, while more complex enclosures can have holes cut for connectors, displays, and other components and can even be silkscreened, molded in a special color, and fabricated to a special size.